0102030405

WPC Outdoor Grille Panels for House Decoration

Application scenarios

WPC wall panels, with their waterproof, wear-resistant, environmentally friendly and weather-resistant properties, are suitable for various types of Spaces. In the home, the kitchen walls are resistant to oil stains and easy to clean, the bathroom walls are mold-proof, and the balcony walls are resistant to sun exposure and rain. The background wall of the guest bedroom can be customized with wood grain to create a natural atmosphere.

In commercial Settings, the walls of restaurants are impact-resistant, easy to maintain, and suitable for frequent use. The milk tea shop uses it as a partition, which is both aesthetically pleasing and practical. In outdoor scenarios, it is used for courtyard fences and the exterior walls of villas. It is anti-aging and waterproof, reducing maintenance costs. It is used for park landscape walls, taking into account both safety and aesthetics, and fully meeting different needs.

Production Description

Dimension measurement and cutting: Before installation, accurately measure the wall dimensions, cut the wall panels according to the actual dimensions, and reserve 3-5mm expansion joints (to cope with thermal expansion and contraction). When cutting, use a special saw blade to keep the cut smooth and avoid burrs that may affect the aesthetic appearance of the splicing. After cutting, clean up the debris from the board to prevent hollowing during installation.

Fixation method control: Prioritize the use of snap-on installation, with the snap-on spacing controlled at 30-40cm to ensure uniform force distribution. If the adhesive type is used, WPC-specific eco-friendly adhesive should be selected. The adhesive layer thickness should be uniform (2-3mm). After pasting, press for 15-20 minutes. Check for no hollowing before installing the next piece to avoid loosening due to adhesive leakage.

Detail sealing and edge finishing: Special sealant is used to fill the joints of the wall panels to prevent water vapor from seeping in. The corners and the right and right corners are sealed with the matching edge strips. The edge strips should be closely attached to the wall panels, with a gap of no more than 1mm. For the openings of sockets, switches, etc., use a dedicated hole opener for precise operation, and seal the edges with sealant to enhance the overall sealing performance and aesthetic appeal.

Differentiation advantage

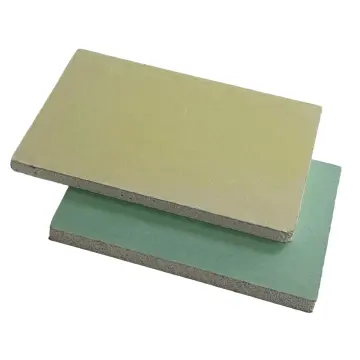

Our company's WPC boards are made with a unique formula, integrating high-quality wood fibers and high-performance plastics, and are pressed through advanced technology. The board structure is compact, and its impact resistance is 30% higher than that of ordinary boards. In daily use, it is not easy to leave marks or damage when tables and chairs collide or when scratched by heavy objects. Its outstanding waterproof and moisture-proof performance enables it to remain stable even in an environment with a humidity of over 90%, without experiencing mold growth, expansion or deformation. It also has strong UV resistance. Even after long-term outdoor use, it will not fade or crack, with a service life of over 25 years, far exceeding similar products. It reduces replacement costs and creates a durable space for you.

The benefits of choosing us

We offer three major series to meet different design requirements:

Natural wood grain series: 6 types of biomimetic textures such as teak, walnut, and red cedar, with three-dimensional embossing treatment on the surface

Modern Geometry Series: Rhombus/Wave/grid hollowed-out shapes, supporting RGB custom colors

Industrial style metal series: Aluminum plating with brushed finish, bronze matte finish and other metallic textures

All products support size customization (up to 6 meters per piece), and corner parts and end fittings are fully supplied as a set, perfectly matching the irregular building structure.