0102030405

PVC ceiling panels for interior decoration

Production Description

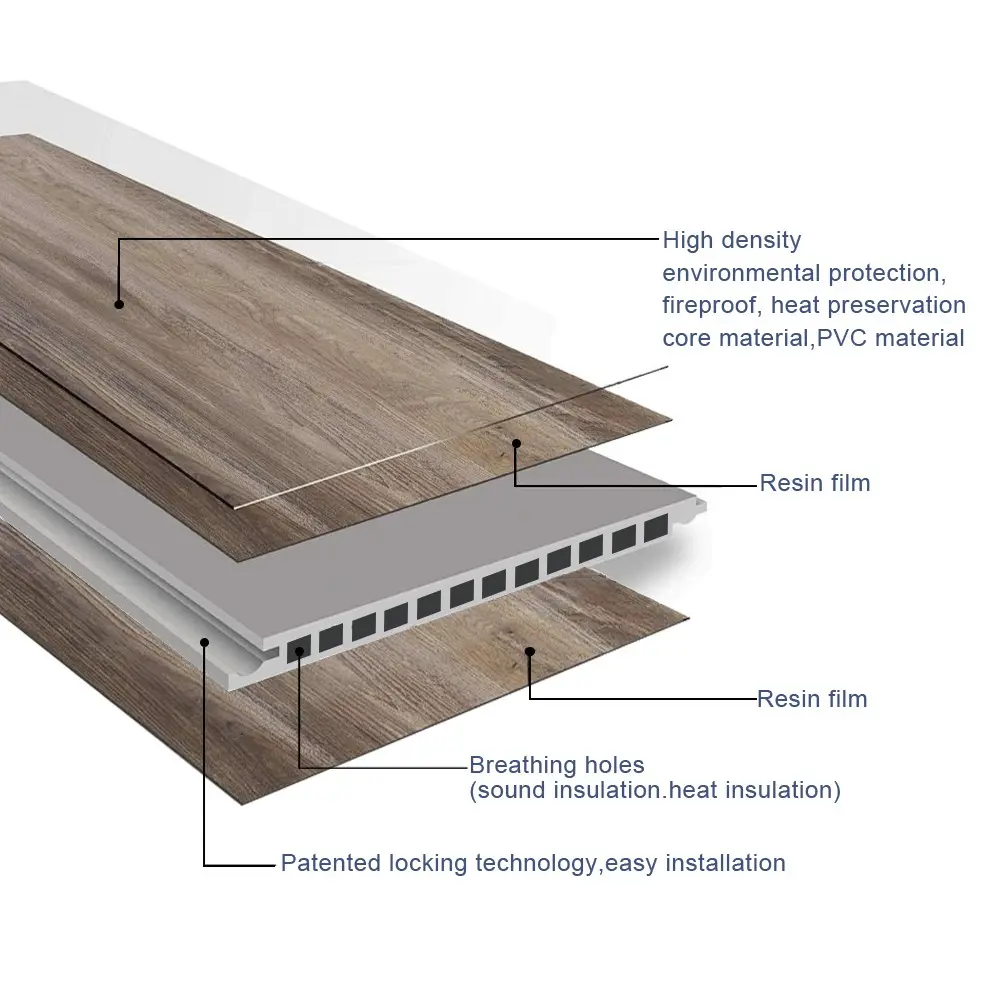

Our company's PVC ceilings are produced through a refined production process. In terms of raw materials, medical-grade PVC resin is carefully selected and precisely proportionally combined with anti-aging agents and B1-grade flame retardants. It does not release formaldehyde and takes into account both environmental protection and fire resistance.

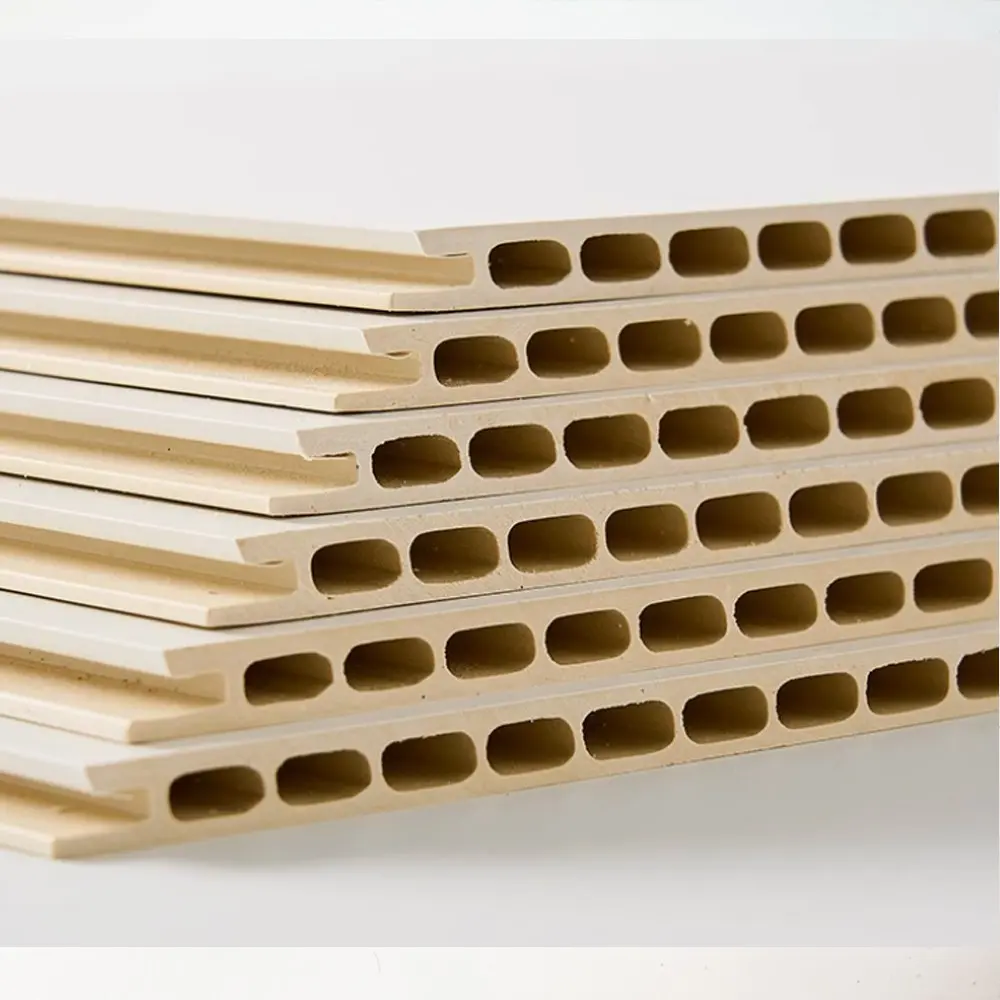

The forming process adopts an integrated extrusion and calendering technology. After high-temperature melting, it is precisely shaped by a mold. The thickness error of the sheet is ≤0.1mm, avoiding height differences during splicing. At the same time, impact modifiers are injected to enhance the toughness of the sheet and reduce damage during transportation and installation.

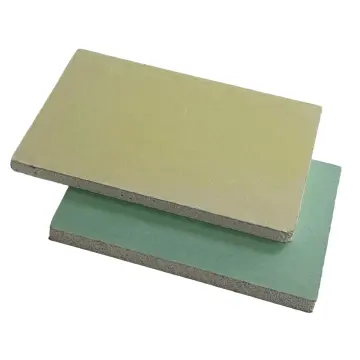

The surface treatment adopts a double-layer lamination process. First, a waterproof base material film is covered, and then an antibacterial decorative film is laminated. Through high-temperature bonding at 120℃, it ensures that the film layer is not easy to fall off, achieving a dual effect of anti-fouling and antibacterial. Finally, through texture pressing technology, wood grain, stone grain and other textures are replicated to restore the natural feel. The entire process is fully automated and monitored to ensure consistent quality for each board.

Differentiation advantage

Our company's PVC ceiling has a significant competitive edge: the raw material is medical-grade PVC resin, combined with precisely proportionally formulated B1 grade flame retardants and anti-aging agents, free of formaldehyde and durable. Other companies mostly use ordinary PVC, which is prone to releasing harmful substances and has weak fire resistance.

The extrusion calendering integrated process is used for forming, with a thickness error of no more than 0.1mm. Anti-impact modifiers are also injected to prevent damage. Other companies often have uneven sheet thickness and are prone to cracking during transportation and installation due to simple processes.

The surface is a double-layer film laminated at 120℃, which is anti-fouling, antibacterial and does not fall off. Other companies mostly use single-layer films, which are prone to falling off and have no antibacterial effect.

The entire process of automated monitoring ensures consistent quality. Other companies rely on manual inspection, often resulting in unstable quality control issues. Its comprehensive advantages far exceed those of its peers.

Application scenarios

These versatile panels find applications across diverse settings:

Residential: Ideal for kitchen ceilings, bathroom cladding, basement finishing and balcony ceilings

Commercial: Widely used in office partitions, restaurant backdrops, retail store displays and hospital interiors

Special Environments: Perfect for clean rooms, laboratories and food processing units due to their hygienic properties The panels can be directly installed over existing surfaces (concrete, plywood or metal frames), making them excellent for renovation projects. Their lightweight nature (2-3kg/sqm) reduces structural load requirements.

The benefits of choosing us

By choosing us as your supplier, you can enjoy multiple core advantages

1.International standard quality guarantee

Our order default rate is 0. We always put the interests of our customers first. Our products have passed international certifications such as CE and ISO. The fire resistance grade and sound insulation performance meet the standards of mainstream markets in Europe, America, Southeast Asia, etc. Each batch of goods is accompanied by an authoritative test report to ensure smooth customs clearance and compliant use in the local area.

2. Stable and efficient supply chain

With our own factory and long-term cooperative logistics providers, we can handle bulk orders of over 100,000 square meters. The transportation method and delivery time can be communicated at any time. We have sufficient inventory of goods, effectively avoiding the risk of supply disruption and ensuring the progress of our customers' projects.

3. Customized service capabilities

The size, thickness and surface treatment (such as moisture-proof coating, antibacterial process) can be adjusted according to customer requirements, or a customized solution can be formulated for you. Neutral packaging or customization of customer brands is supported to meet the differentiated needs of different markets.

4. Full-process support for foreign trade

We offer flexible trade terms such as FOB and CIF, and have a professional foreign trade team to assist with customs declaration, sea transportation, documentation and other matters. We provide 7× 24-hour multilingual communication to break down communication barriers in cross-border cooperation.