0102030405

Premium PVC Composite Wall Panels for Interior and Exterior Use

Production Description

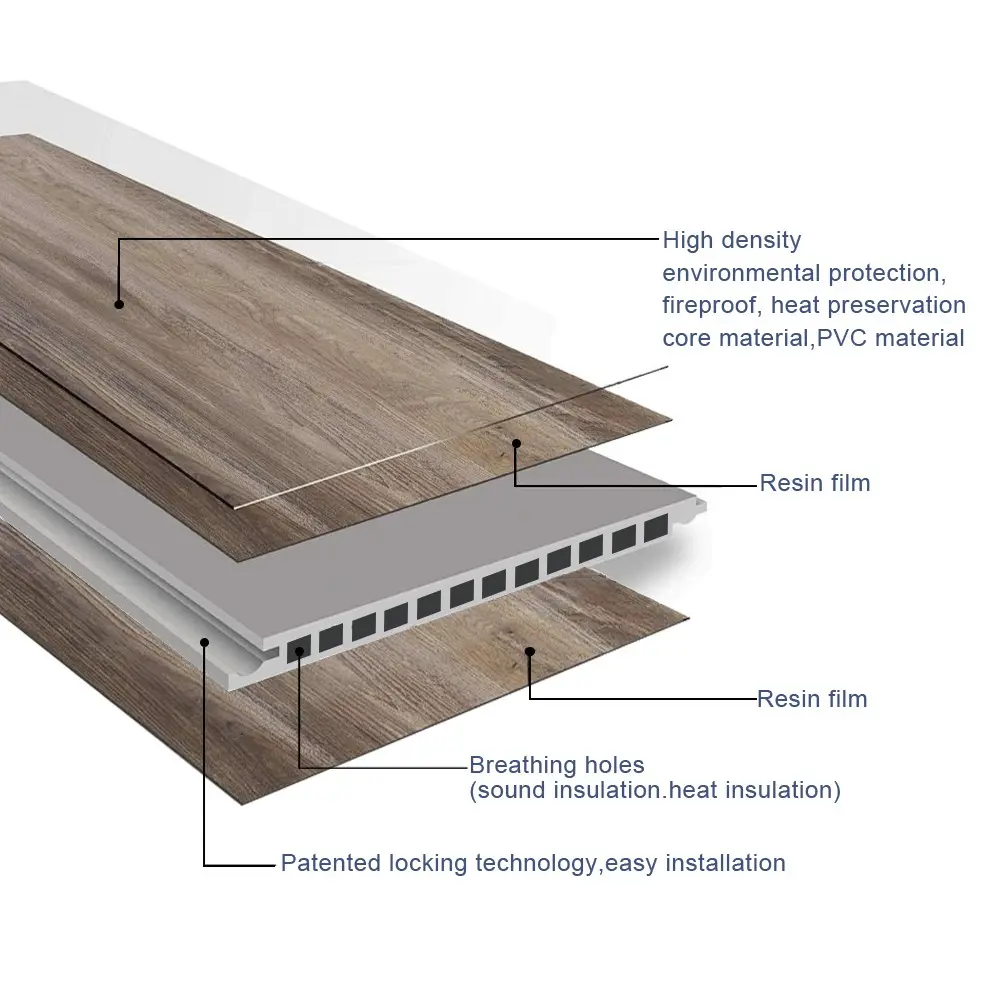

The production of PVC interior wall panels requires multiple meticulous processes. Firstly, high-quality PVC resin is used as the base material, and environmentally friendly stabilizers, toughening agents and anti-aging agents are added in proportion to avoid harmful additives and ensure the environmental friendliness of the finished product.

Subsequently, the mixed raw materials are put into a high-speed mixer and thoroughly stirred at a temperature of 120-150℃ for 30 minutes to ensure uniform dispersion of the components and lay a foundation for subsequent molding. Then it is sent into a conical twin-screw extruder, where it is extruded into a slab of the preset thickness through a die. At the same time, the extrusion speed and cooling water temperature are controlled to prevent the slab from deforming. Finally, after surface lamination or UV printing treatment, various textures such as wood grain and stone grain are created. Then, they are precisely cut to the standard size. Each batch of finished products needs to be tested for flatness and impact resistance to ensure the stability and compliance of the process.

Differentiation advantage

Raw material and environmental advantages: Only high-quality PVC resin and environmentally friendly stabilizers/toughening agents are used. Harmful additives are resolutely eliminated to avoid environmental risks brought by inferior additives from the source. The environmental friendliness of the finished product far exceeds that of some of the products of the same industry containing toxic additives.

Advantages in process accuracy: The stirring stage precisely controls the temperature at 120-150℃ and maintains it for 30 minutes for uniform mixing. When paired with a conical twin-screw extruder, the extrusion speed and cooling water temperature are simultaneously controlled, effectively preventing sheet deformation. The flatness and stability of the product are superior to those of competing products with ambiguous process parameters.

Application scenarios

The bedroom/children's room, with no harmful additives in the raw materials (echoing the environmental protection advantages of the raw materials), has zero formaldehyde release, meeting the safety requirements for sleep and children's activities. The living room, with its high flatness guaranteed by craftsmanship and diverse textures printed by UV (corresponding to the precision of craftsmanship and customization advantages), can match modern, light luxury and other styles. The wear-resistant surface can withstand furniture collisions and will not deform over long-term use.

The kitchen and bathroom Spaces, with the waterproof property of PVC base material and the stability of the process, are not afraid of water vapor and oil stains. Cleaning only requires wiping with a damp cloth. In densely populated areas such as corridors and foyers, finished products that have passed impact resistance tests (with quality control advantages) can withstand daily bumps and knocks, combining practicality and aesthetics, and are suitable for all needs of home and commercial decoration.

The benefits of choosing us

By choosing us as your supplier, you can enjoy multiple core advantages

1.International standard quality guarantee

Our order default rate is 0. We always put the interests of our customers first. Our products have passed international certifications such as CE and ISO. The fire resistance grade and sound insulation performance meet the standards of mainstream markets in Europe, America, Southeast Asia, etc. Each batch of goods is accompanied by an authoritative test report to ensure smooth customs clearance and compliant use in the local area.

2. Stable and efficient supply chain

With our own factory and long-term cooperative logistics providers, we can handle bulk orders of over 100,000 square meters. The transportation method and delivery time can be communicated at any time. We have sufficient inventory of goods, effectively avoiding the risk of supply disruption and ensuring the progress of our customers' projects.

3. Customized service capabilities

The size, thickness and surface treatment (such as moisture-proof coating, antibacterial process) can be adjusted according to customer requirements, or a customized solution can be formulated for you. Neutral packaging or customization of customer brands is supported to meet the differentiated needs of different markets.

4. Full-process support for foreign trade

We offer flexible trade terms such as FOB and CIF, and have a professional foreign trade team to assist with customs declaration, sea transportation, documentation and other matters. We provide 7× 24-hour multilingual communication to break down communication barriers in cross-border cooperation.