0102030405

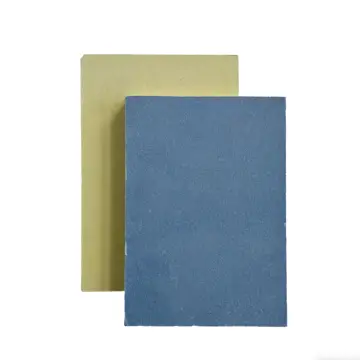

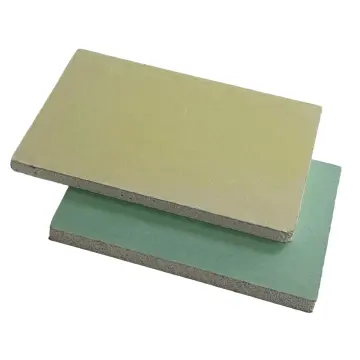

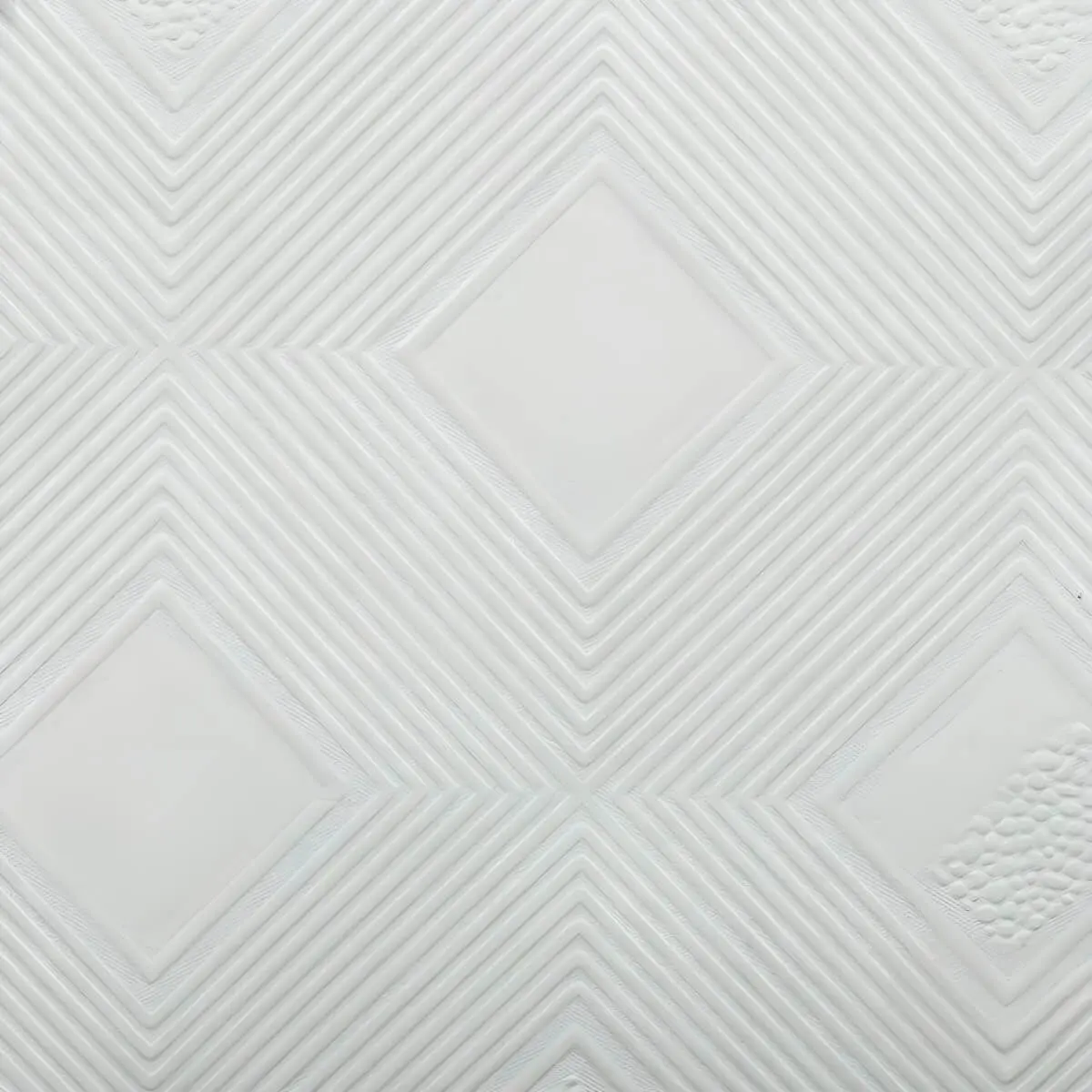

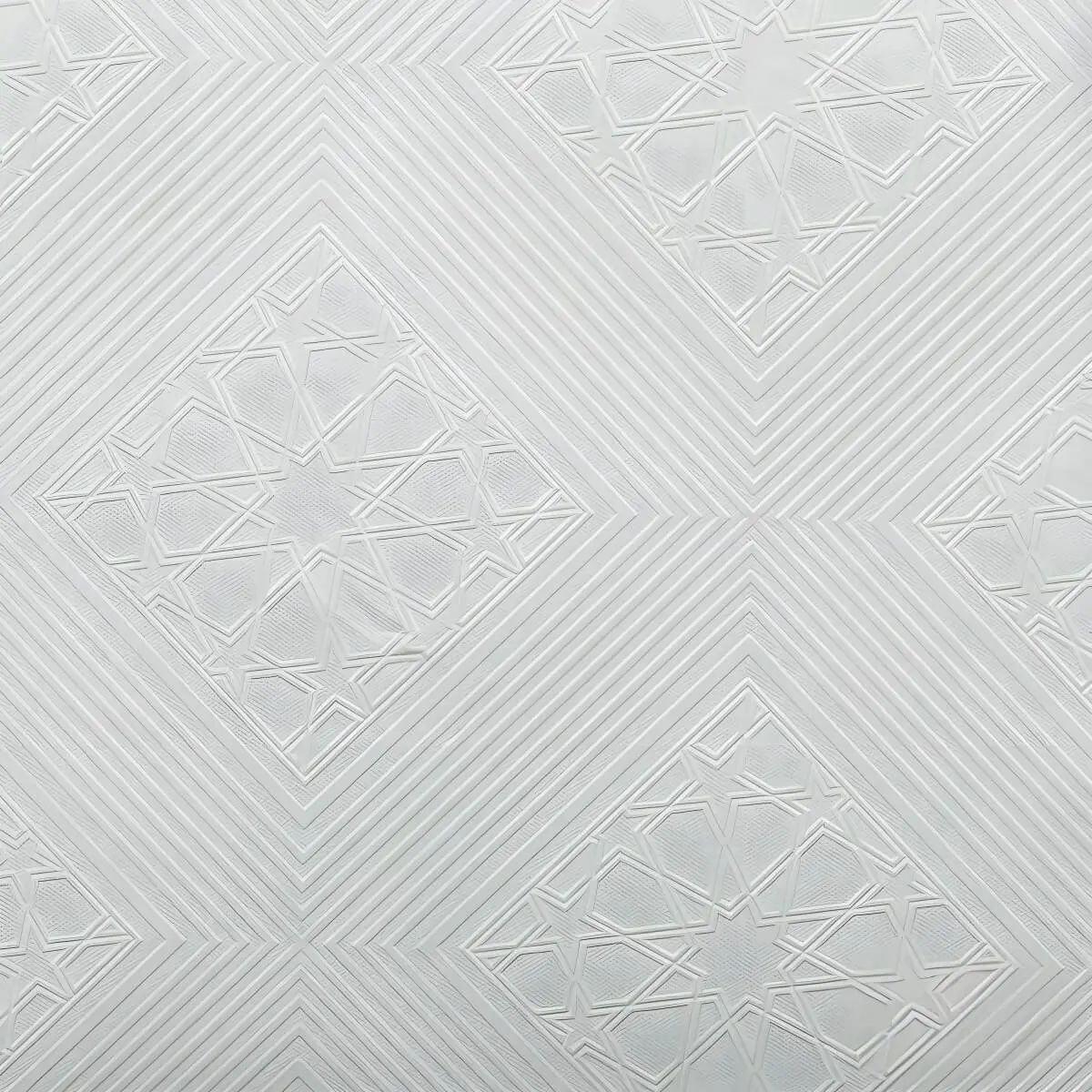

Plaster Ceiling / PVC Gypsum Board

Production Description

Selected raw materials and proportions: High-purity natural gypsum is chosen, impurities are removed and ground into fine powder. Reinforcing glass fiber and environmentally friendly adhesives are added in precise proportions to ensure uniform mixing of raw materials, laying a foundation for the crack resistance of the board.

High-pressure forming process: Mixed raw materials are injected into custom molds, and then pressed under 30MPa high pressure to expel internal air, making the board structure dense, reducing pores, enhancing load-bearing and moisture-proof capabilities, while ensuring dimensional accuracy.

Low-temperature slow drying and curing: The formed boards are placed in a constant-temperature drying room and slowly dried at a low temperature of 50-60℃ to prevent cracking caused by high temperatures. After 72 hours of gradual dehydration and curing, the material stability is enhanced.

Fine surface treatment: After drying, the surface of the board is ground to remove burrs. Then, according to requirements, surface processing such as film coating and spraying is carried out to ensure a smooth and flat surface, which is both decorative and durable.

Differentiation advantage

Stronger crack resistance and durability: Carefully selected high-purity gypsum and precisely proportioned reinforced glass fiber, combined with a 30MPa high-pressure molding process, the board structure is dense and pore-free, with a 40% increase in crack resistance compared to ordinary products. It is less likely to deform or fall off over long-term use.

More reliable moisture-proof and load-bearing: High-pressure pressing reduces internal moisture residue, combined with low-temperature slow drying and curing (72 hours of constant temperature), the board has excellent moisture-proof performance, is less likely to mold in humid environments, and at the same time, the load-bearing capacity is increased by 25%, suitable for various installation requirements.

The benefits of choosing us

By choosing us as your supplier, you can enjoy multiple core advantages

1.International standard quality guarantee

Our order default rate is 0. We always put the interests of our customers first. Our products have passed international certifications such as CE and ISO. The fire resistance grade and sound insulation performance meet the standards of mainstream markets in Europe, America, Southeast Asia, etc. Each batch of goods is accompanied by an authoritative test report to ensure smooth customs clearance and compliant use in the local area.

2. Stable and efficient supply chain

With our own factory and long-term cooperative logistics providers, we can handle bulk orders of over 100,000 square meters. The transportation method and delivery time can be communicated at any time. We have sufficient inventory of goods, effectively avoiding the risk of supply disruption and ensuring the progress of our customers' projects.

3. Customized service capabilities

The size, thickness and surface treatment (such as moisture-proof coating, antibacterial process) can be adjusted according to customer requirements, or a customized solution can be formulated for you. Neutral packaging or customization of customer brands is supported to meet the differentiated needs of different markets.

4. Full-process support for foreign trade

We offer flexible trade terms such as FOB and CIF, and have a professional foreign trade team to assist with customs declaration, sea transportation, documentation and other matters. We provide 7× 24-hour multilingual communication to break down communication barriers in cross-border cooperation.