The export volume of Chinese WPC wall panels continues to rise, and our company's order growth highlights the vitality of the industry

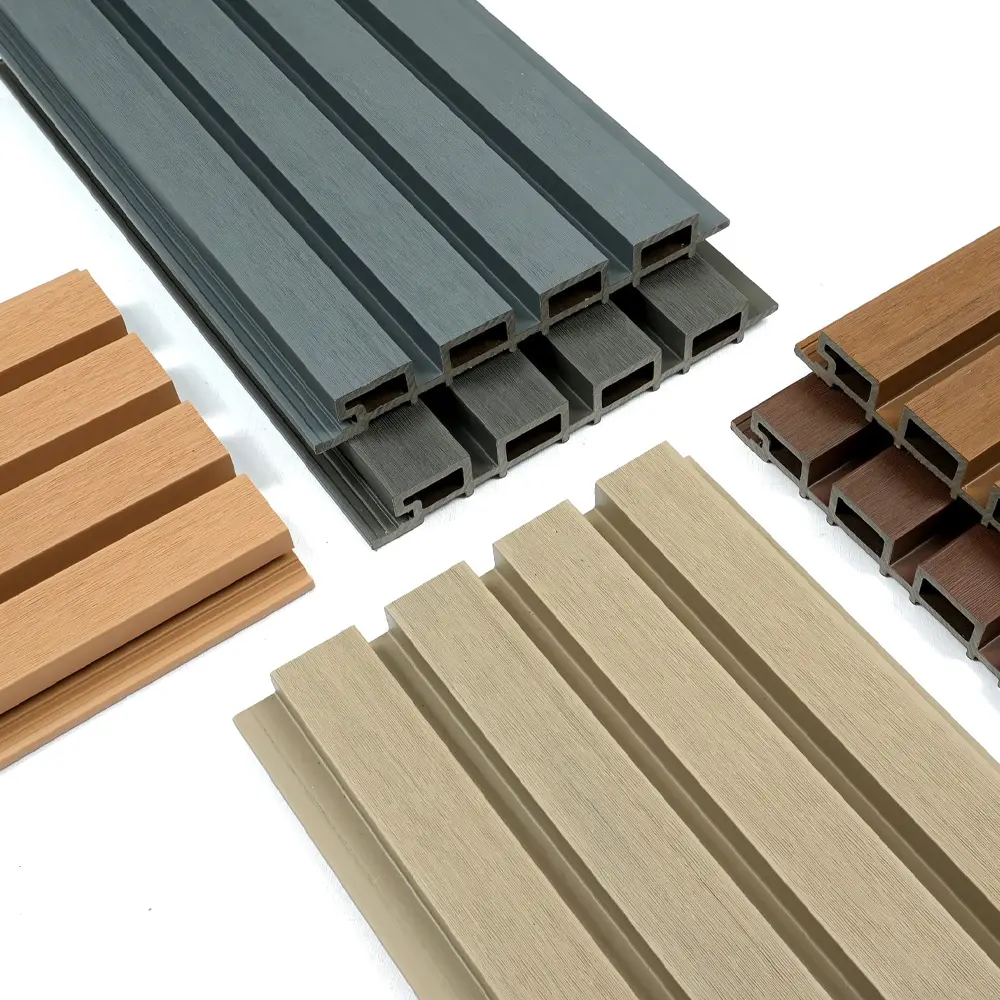

The outbreak of this export boom is due to the upgraded demand for environmentally friendly building materials in the global construction market. As a representative product of wood plastic composite materials, WPC wall panels perfectly integrate natural wood fibers with thermoplastic plastics, retaining the natural texture of wood while possessing the weather resistance of plastic, completely solving the industry pain points of traditional wood being perishable and plastic being difficult to degrade. The WPC wall panels produced by our company have passed the GB/T17657-2013 environmental protection standard certification, with no detection of formaldehyde and heavy metals. At the same time, they meet the GB8624-2012 A-level fire protection standard and perform excellently in humid climates in Southeast Asia, high-temperature environments in the Middle East, and environmental protection systems in Europe and America.

The core advantage of "good quality and low price" has become the key for Chinese WPC wall panelsto explore the international market. Compared to solid wood wall panels, our products can save 50% of material costs, eliminating additional costs such as painting and anti-corrosion. Additionally, old walls can be directly covered and installed, saving 50% of construction time and 90% of construction waste. With the advantage of Linyi industrial cluster, the company integrates upstream raw material supply, midstream production, and downstream logistics and customs declaration resources, achieving an annual production of over 10 million square meters of WPC Wall Panels. The large-scale production further reduces costs, and the product price is only 60% -70% of similar products in Europe and America.

At present, our WPC wall panels have been exported to more than 70 countries and regions around the world. We specialize in high-end craft products such as deep embossing and wire drawing in Europe and America, and have passed FSC certification to meet local environmental protection needs; Launch thick plates of 12mm and above in the Middle East market, with stone and wood grain finishes to meet high-end decoration needs; The anti moisture and anti mold series customized for the Southeast Asian market has become the preferred building material for local residential construction. Recently, the company has added three UV co extrusion production lines, which can provide personalized customization services according to customer needs. The order repurchase rate has remained above 85% for three consecutive quarters.

The global building materials market research report points out that sustainable materials and modular decoration have become international trends, and WPC wall panels, as the core adaptive product, will exceed a global market size of 30 billion US dollars in the next five years. In the face of opportunities, our company will further upgrade our research and development center, focusing on tackling technologies such as extreme weather resistance and intelligent assembly. At the same time, we will expand our overseas warehousing center, improve global delivery efficiency, and continue to rely on the advantages of Chinese manufacturing to deeply cultivate the international market.