In 2025, the PVC wall panel industry: Technological innovation and green transformation drive market expansion

With the upgrading of the architectural decoration industry's demands for environmental protection and functionality, the PVC wall panel market is expected to show a significant growth trend in 2025. The latest industry report shows that the market size of PVC wall panels in China is expected to exceed 35 billion yuan, with a compound annual growth rate of 8.5%, and is expected to exceed 60 billion yuan by 2030. The core driving force for industry growth comes from three major innovation directions

Breakthroughs in material technology and a dense emergence of patents

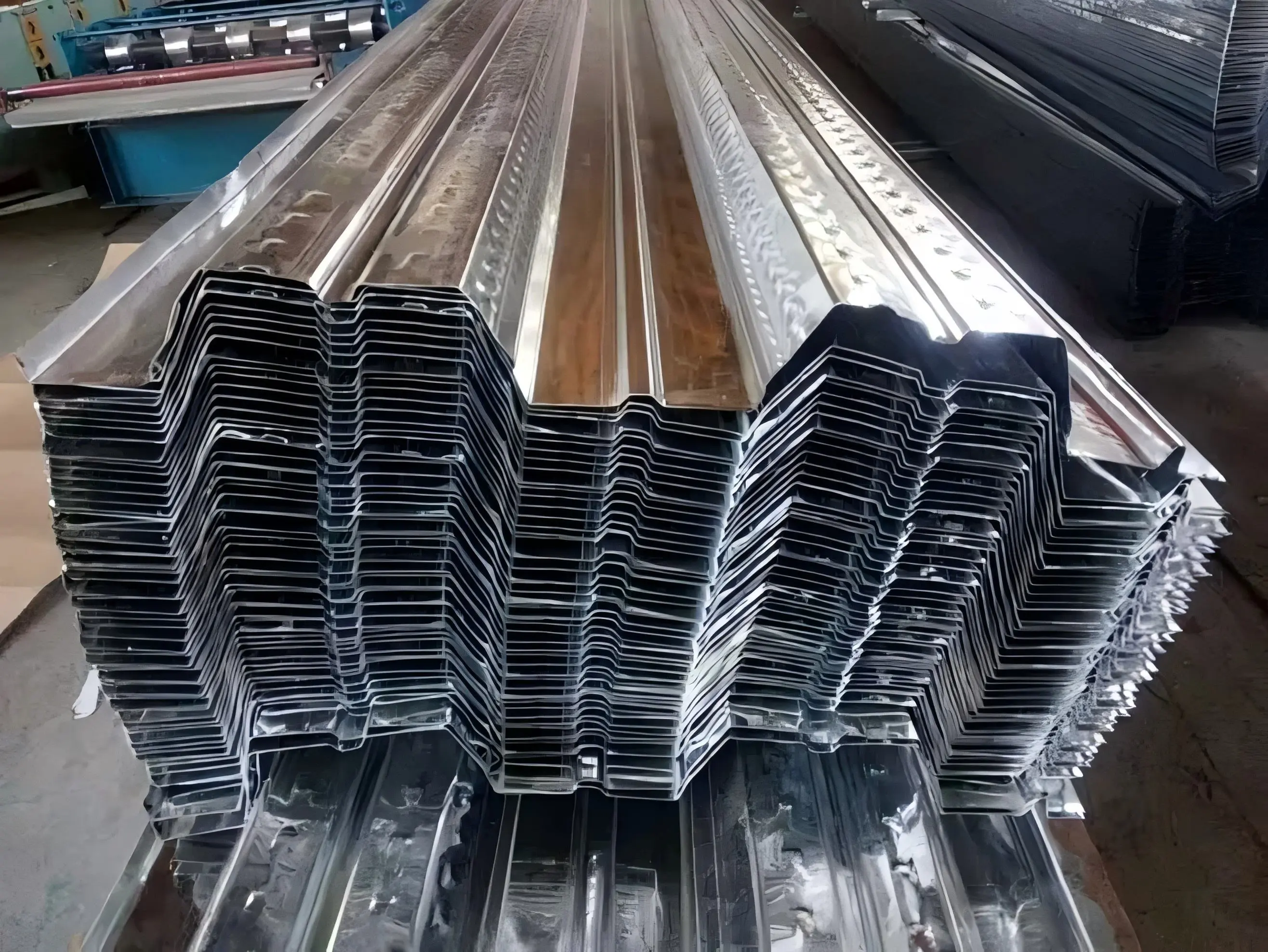

Enterprises promote product iteration through technological research and development. The PVC wall panels for building insulation launched by Haining Hongying feature a hollow partition design, with built-in insulation fillers and wavy insulation layers. Their insulation performance is enhanced by 40%, and they are easy to install. The snap-on PVC wall panels developed by Qingdao Yingfu feature a detachable structure design, achieving a secondary utilization rate of over 90%, significantly reducing decoration waste. The anti-slip PVC Board of Hangzhou Yichao Board Industry has reduced the risk of slipping by 60% through the design of the drainage port and has been widely used in scenarios such as supermarkets and gyms.

Environmental protection policies are driving the upgrading of green production

At the policy level, the DB34/4812.6-2024 standard implemented in Anhui Province stipulates that the VOC emissions of PVC wall panels should be ≤68µg/m³, which is 92% lower than that of traditional processes. Lu 'an Lisheng New Materials has invested 6 million yuan to build a fully enclosed production line. It uses catalytic combustion devices to treat waste gas and wastewater, with a reuse rate of 85%, setting a benchmark for green production in the industry. Leading enterprises in the industry have replaced traditional PVC with bio-based materials, increasing the recyclable ratio of their products to 70% and meeting the EU REACH certification standards.

Multi-dimensional expansion of application scenarios and intelligent penetration

In the business sector, Shanghai Bingo Western Restaurant has adopted moisture-proof and mold-proof PVC wall panels in its kitchen area. The easy-to-clean surface feature of these panels has reduced maintenance costs by 30%. In industrial scenarios, heat transfer printing technology enables the customization of surface textures for PVC wall panels, and laser cutting technology enhances the processing accuracy to 0.1mm, meeting the personalized demands of automotive interior parts. In terms of intelligent production, leading enterprises have introduced AI visual inspection systems, reducing the product defect rate from 3% to 0.8%. At the same time, they have achieved full-process monitoring of the supply chain through the Internet of Things.