Gypsum board + light steel keel: Decoding the Golden Combination for Modern Ceiling Engineering

As the core of the framework, the combination of Light Steel Keel and gypsum board must follow strict compatibility standards. According to the technical specifications of the China Building Materials Federation, U-shaped light steel keels are preferred for load-bearing scenarios. The spacing of main keels is controlled at 900-1200mm, and the spacing of medium and small keels is 500-600mm. For non-load-bearing scenarios, T-shaped keels can be used, and a 9.5mm thick ordinary gypsum board with paper surface can meet the requirements. In the ceiling renovation project of a certain office building, the construction party adopted U50 main keel +U38 secondary keel combined with 9.5mmgypsum board. By precisely controlling the keel spacing and camber, they successfully solved the problem of the flatness of the 300-square-meter large ceiling.

The scientific construction process is the key guarantee for the matching effect. The industry standard process flow shows that the elevation and the position of the keel should be marked first, then the φ8 hanger rods should be installed to fix the main keel. After leveling, the medium and small keels should be assembled in sequence. Finally, the gypsum board should be laid and fixed with self-tapping Screws, with the screw spacing controlled at 200-300mm. It is worth noting that a 5mm gap should be reserved at the joints of gypsum boards. After filling with jointing gypsum and attaching fiberglass mesh fabric, it can effectively prevent cracking in the later stage. After this process was applied in commercial projects in East China, the construction efficiency increased by 30% and the rework rate dropped below 2%.

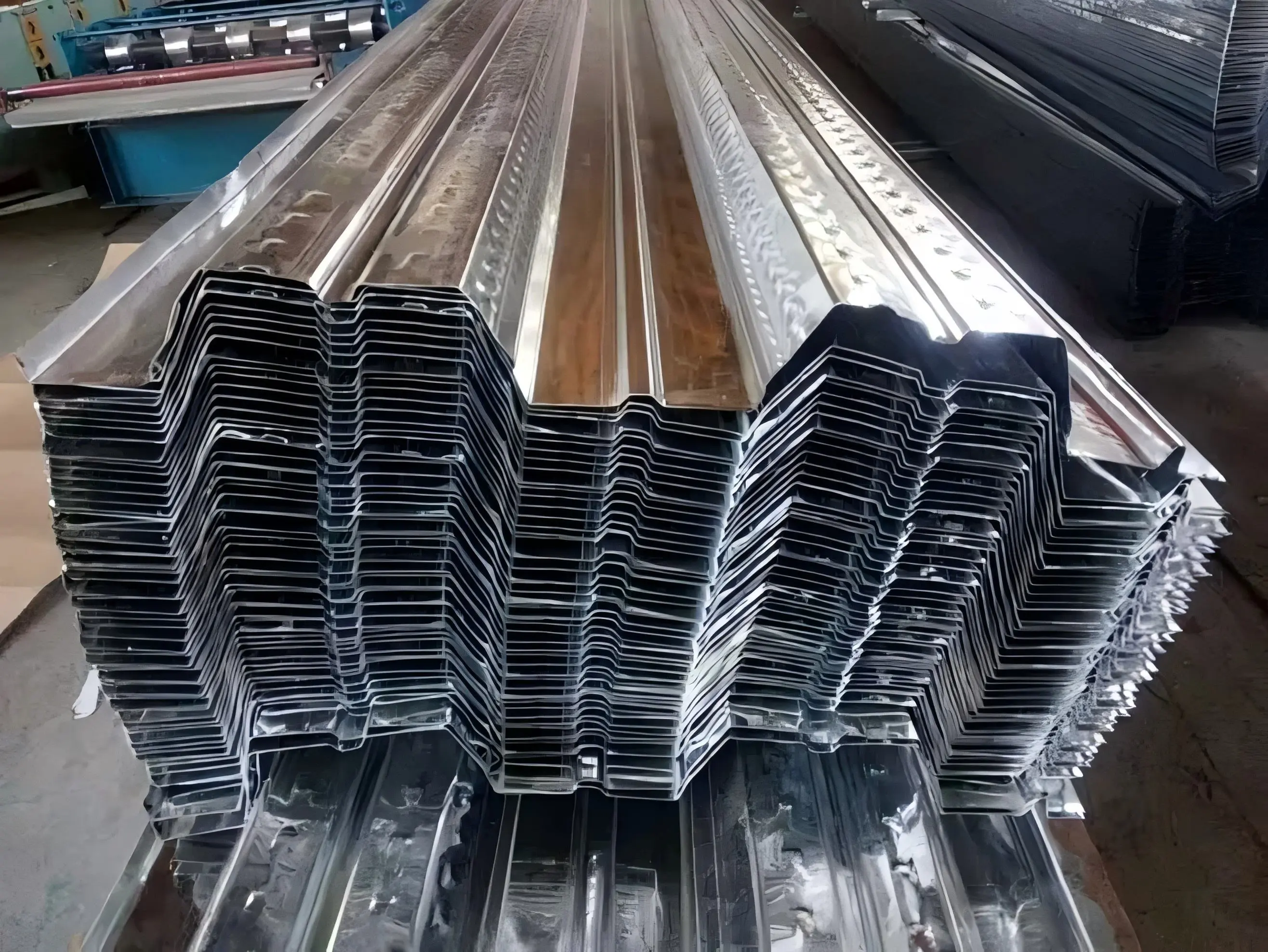

The market landscape also confirms the advantages of this combination. Leading enterprises such as Beixin Building Materials and Taishan Gypsum have formed a coordinated production capacity layout of gypsum board and light steel keel. In 2023, their industry CR5 shares reached 67% and 39% respectively. Experts remind that when customers make a choice, they should pay attention to the anti-rust treatment of light steel keel and the environmental protection grade of gypsum board. In a humid environment, it is recommended to use moisture-proof gypsum board in combination with hot-dip galvanized keel to ensure the quality and service life of the project.

With the deepening of the "dual carbon" strategy, the green advantages of gypsum board and light steel keel will be further highlighted. This golden combination is expected to be more widely applied in the fields of urban renewal and prefabricated buildings.