A large quantity of WPC wall panels are in stock and coming off the production line, empowering the efficient delivery of the green building market

The current global WPC materials market is expanding at an annual growth rate of 6% to 9%, and the trends of green buildings and prefabricated construction are driving a sharp increase in industry demand. The WPC wall panels produced in stock this time are made through a composite process of Recycled wood fiber and eco-friendly plastic, featuring both the texture of real wood and the weather resistance of plastic. They have passed authoritative tests and met seven core indicators including water resistance, fire resistance, scratch resistance and mold resistance, making them suitable for various scenarios such as home decoration, hotel renovation and commercial venue construction. The product supports seamless splicing of 3000mm and customization of multiple patterns such as stripes and checks. It can also integrate additional functions like sound absorption and heat insulation according to requirements, perfectly meeting the market's dual demands for "aesthetics + functionality".

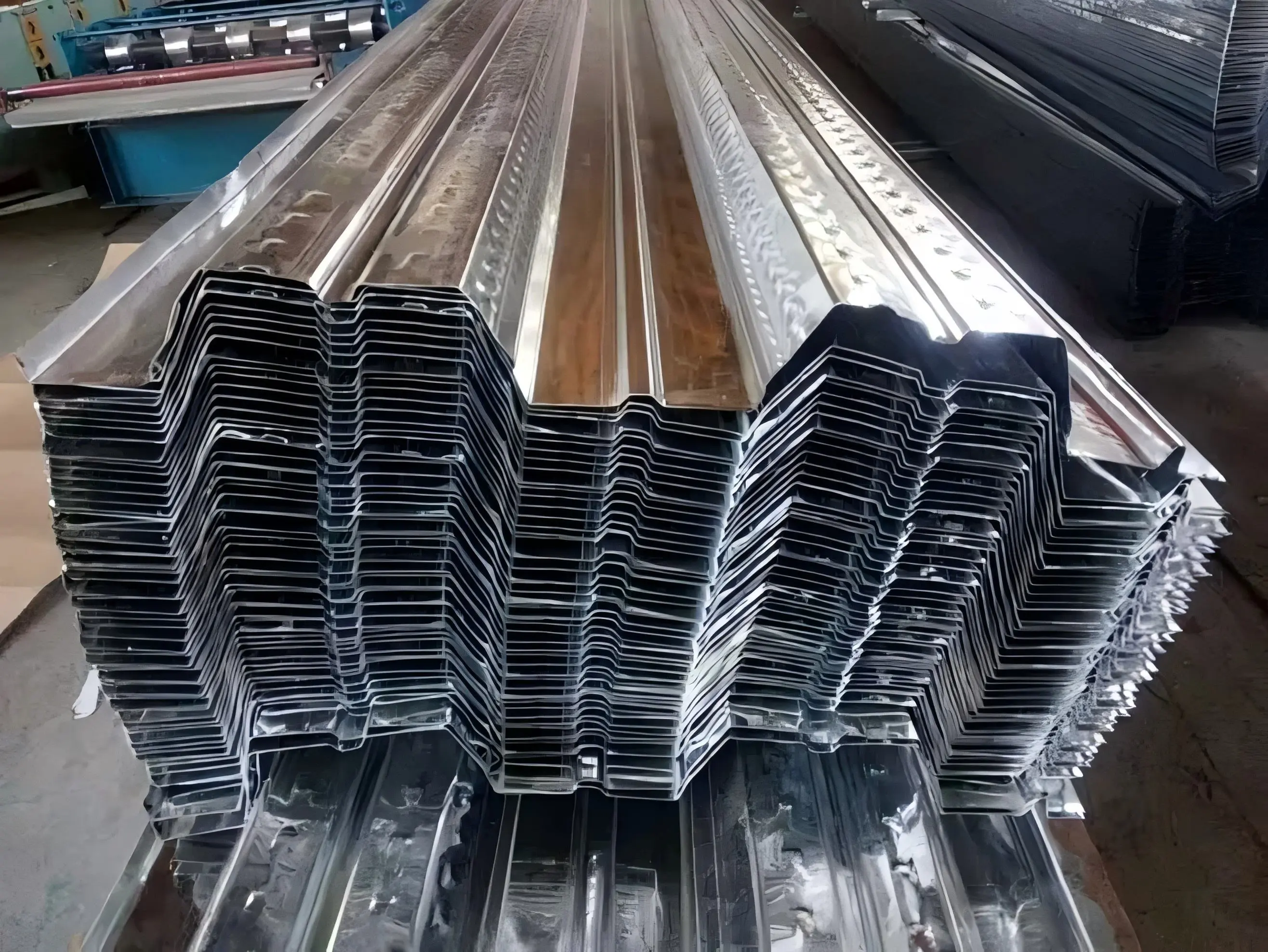

The successful production of this large batch of spot goods is attributed to the intelligent production line that the company has invested in and built in recent years. This production line adopts fully automatic extrusion and UV coating processes, achieving full-process digital control from raw material proportioning to finished product inspection. Its daily production capacity is 40% higher than that of traditional production lines, and its weekly supply capacity is stable at over 10,000 pieces. During the production process, the enterprise strictly adheres to the EU building product regulations and domestic green building materials standards. All in-stock products have passed third-party authoritative certifications to ensure the consistency of product quality.

"Spot supply will completely solve the industry's pain points of 'long customization cycles and difficulty in fulfilling urgent orders'." " The production manager of the company stated that the traditional WPC wall panel customization delivery takes 15 to 20 days, while the current in-stock products can be dispatched within 72 hours after order confirmation. For scenarios such as infrastructure repair and commercial project rush, the delivery efficiency has increased by over 60%. At present, the spot inventory has covered mainstream specifications, while reserving capacity for personalized customization, which can quickly respond to customers' special size and color requirements.

It is understood that after the release of the spot information, it has attracted inquiries from construction enterprises and foreign trade distributors in many places. Three intention orders have been reached for the first batch of spot goods. The company's marketing director disclosed that in the future, relying on the advantage of spot goods, they will introduce an "urgent order green channel" and preferential policies for bulk purchases. Against the backdrop of the accelerated development of global green buildings, the company will continue to expand its production capacity reserves in the future, empower customers to reduce costs and increase efficiency with high-quality inventory, and consolidate its core position in the industry supply chain.