A comprehensive analysis of the process and application fields of light steel keel as a new favorite in construction

The core competitiveness of light steel keellies in the international compatibility features of its three major products. Firstly, it features outstanding lightweight and high-strength performance. Made of 550MPa grade high-strength galvanized steel strips, it reduces weight by over 30% compared to traditional concrete structures. The 0.8mm thick ceiling keel can bear a load of 50-60kg/㎡, meeting the demands of high-load scenarios such as shopping malls in Europe and America and exhibition halls in the Middle East. Secondly, its green attributes are significantly in line with global standards, with a recycling rate of over 95%. The proportion of high-end products with a hot-dip galvanizing weight of ≥90g/㎡ has exceeded 41%, fully meeting the green building materials evaluation standards and having passed green building materials certifications such as the EU CE and the US UL. Thirdly, it has strong customization capabilities and is well-suited for cross-border projects. Through BIM technology, it achieves a prefabrication rate of over 60%, which can meet the spatial layout requirements of building codes in different countries.

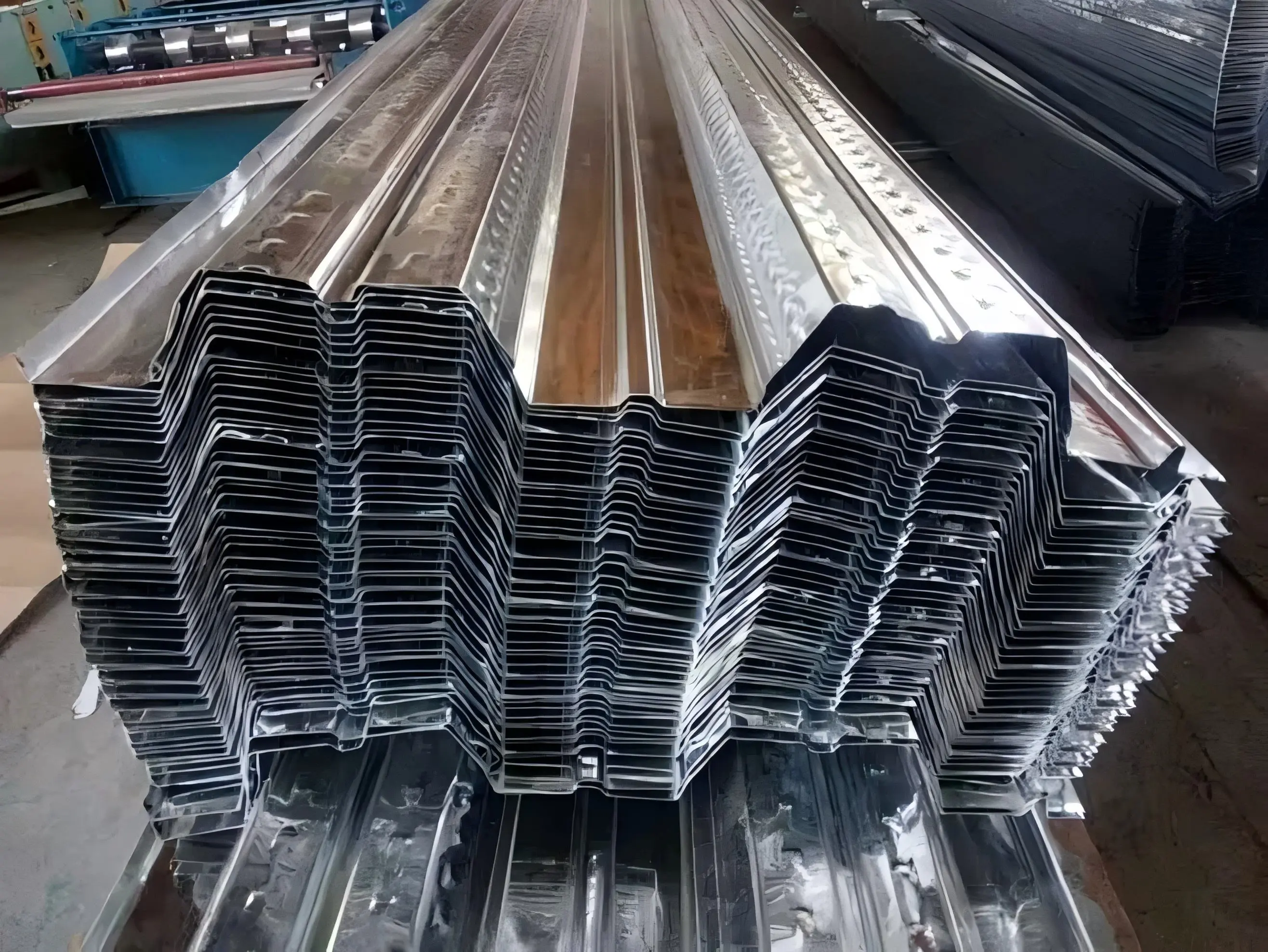

The international upgrading of production processes has become the core of trade competitiveness. At present, the mainstream export enterprises adopt cold rolling forming technology. After being processed by intelligent welding robots, the automation rate of the production line reaches over 85%, which can precisely match the size standards of different regions such as Europe, America and Southeast Asia. The environmental protection process complies with international standards. The hot-dip galvanizing anti-corrosion treatment achieves a globally recognized zinc coating weight of 120g/㎡. Coupled with a digital quality control system, the product qualification rate remains stable at over 99%. Leading enterprises have set up cross-border flexible production lines, established factories in Southeast Asia and Eastern Europe to achieve local delivery, compressed the delivery cycle of customized orders to within 72 hours, and significantly reduced the cost of international trade logistics.

Ms. Zhang, the president of the company, stated that with the advent of the intelligent keel system integrating sound insulation and fire protection functions, light steel keels will extend from a single material to an overall solution, continuously consolidating their core position in the green building industry chain. In the future, with the unification of the global green building certification system, enterprises with environmental protection labels and local supply capabilities will dominate the international trade pattern and continuously consolidate their core position in the global prefabricated building industry chain.