0102030405

Modern 3d Pvc Wall Panels - Innovative Textured Interior Design Solution

Production Description

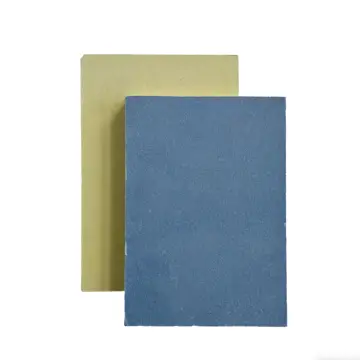

The production of 3D PVC wall panels begins with the precise proportioning of raw materials: environmentally friendly grade PVC resin is selected as the base material, combined with flame retardants, anti-aging agents and waterproof additives, and thoroughly mixed by a high-speed mixer to ensure that the raw materials do not release formaldehyde and have basic protective performance.

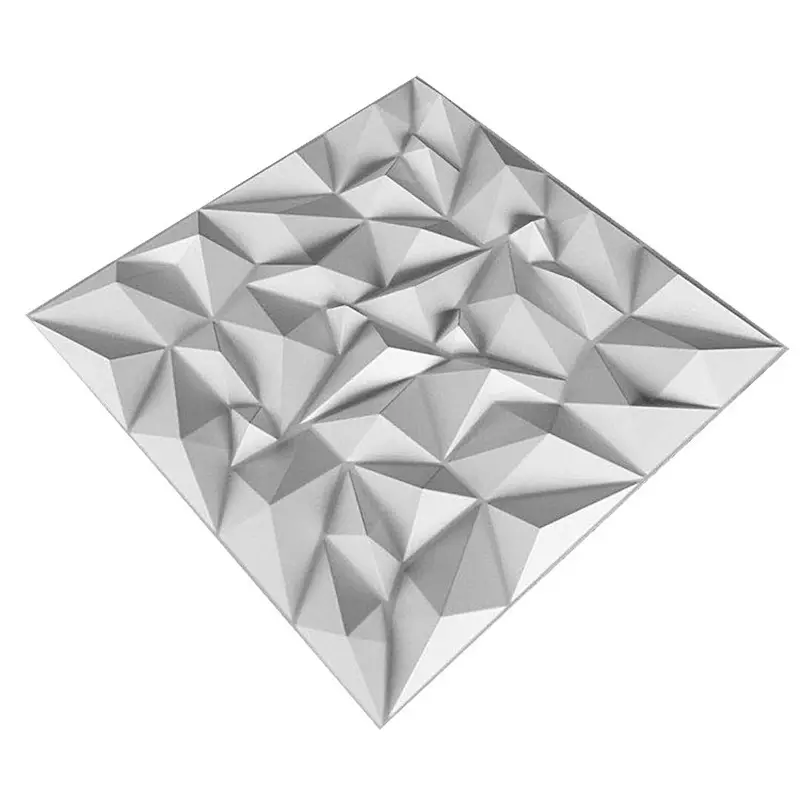

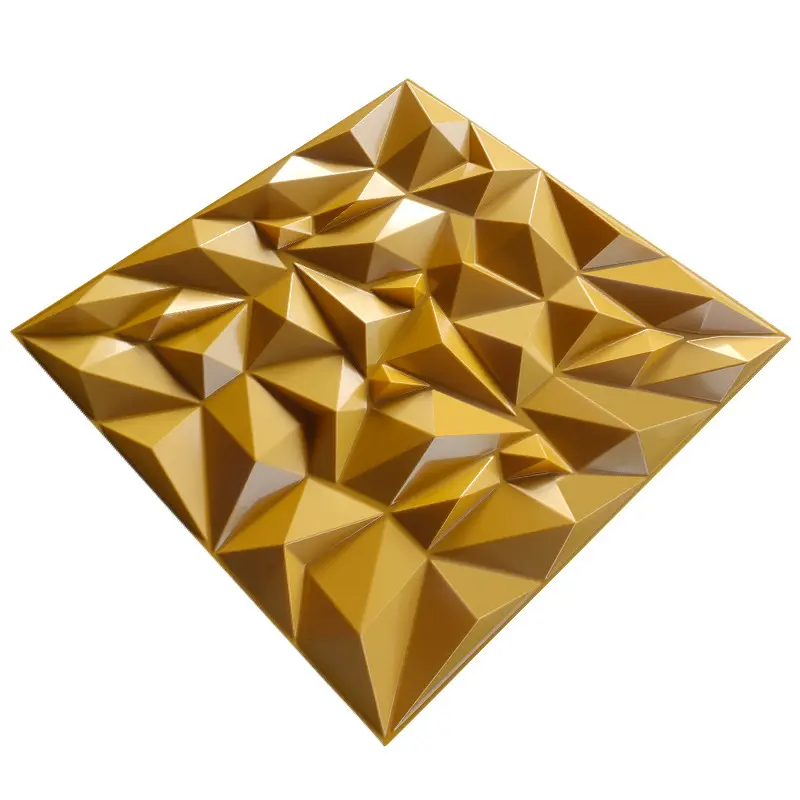

The core 3D forming process adopts the "custom mold + vacuum forming" technique: First, molten raw materials are injected into a dedicated mold for replicating three-dimensional textures. Through constant temperature and high pressure, the raw materials are made to closely adhere to the mold's texture, precisely restoring the embossed concave-convex feeling. For some complex shapes, vacuum forming technology is used to ensure the clarity and three-dimensional effect of the texture.

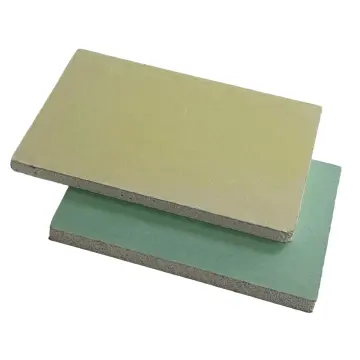

After molding, it undergoes surface strengthening treatment: spraying a wear-resistant and scratch-resistant coating to enhance its impact resistance. Apply another waterproof film layer to enhance the moisture-proof performance. Finally, the dimensional accuracy is adjusted through CNC cutting, and it passes the sampling tests for texture integrity and flame retardancy. Only after passing the tests can it be packaged and sent out of the factory, ensuring the stability of product quality and performance throughout the process.

Differentiation advantage

The advantages of our company's 3D PVC wall panels lie in the control of process details: in terms of raw materials, we carefully select environmentally friendly grade PVC resin and customize flame-retardant/waterproof additives, which are free of formaldehyde and have better protective performance, far exceeding the environmental protection and protective shortcomings of ordinary raw materials in the industry. In the forming stage, custom molds combined with high-temperature calendering and vacuum forming processes are adopted. The texture depth and shape can be adjusted as needed, breaking through the design limitations of fixed molds in the industry and achieving a more detailed three-dimensional effect. The surface is treated with HB-grade wear-resistant coating and special waterproof film. Its scratch resistance and moisture resistance far exceed those of ordinary coating products, and its durability is increased by more than 50%. At the quality control end, the CNC cutting error is ≤0.5mm. With dual sampling tests for texture and flame retardancy, common dimensional deviations and performance non-compliance issues in the industry are eliminated. It takes into account environmental protection, aesthetics and practicality, and has a significant comprehensive competitiveness.

Application scenarios

3D PVC wall panels are suitable for multi-area home decoration: The TV background wall in the living room can be customized with embossed textures, matching modern, light luxury and other styles. The three-dimensional shape highlights the spatial layering. The kitchen and bathroom walls, with their fully waterproof and wear-resistant features, are not afraid of moisture and oil stains. Daily cleaning can be easily wiped clean, solving the problem of mold on traditional walls.

Decorate the headboard wall of the bedroom with it. The environmentally friendly and formaldehyde-free material ensures living safety, and the warm texture can also weaken the coldness of the space. Partial tiling in the entrance hall can create a visual highlight upon entering the house. Its scratch-resistant feature can also handle daily bumps and knocks, taking into account both aesthetics, practicality and living safety.

The benefits of choosing us

By choosing us as your supplier, you can enjoy multiple core advantages

1.International standard quality guarantee

Our order default rate is 0. We always put the interests of our customers first. Our products have passed international certifications such as CE and ISO. The fire resistance grade and sound insulation performance meet the standards of mainstream markets in Europe, America, Southeast Asia, etc. Each batch of goods is accompanied by an authoritative test report to ensure smooth customs clearance and compliant use in the local area.

2. Stable and efficient supply chain

With our own factory and long-term cooperative logistics providers, we can handle bulk orders of over 100,000 square meters. The transportation method and delivery time can be communicated at any time. We have sufficient inventory of goods, effectively avoiding the risk of supply disruption and ensuring the progress of our customers' projects.

3. Customized service capabilities

The size, thickness and surface treatment (such as moisture-proof coating, antibacterial process) can be adjusted according to customer requirements, or a customized solution can be formulated for you. Neutral packaging or customization of customer brands is supported to meet the differentiated needs of different markets.

4. Full-process support for foreign trade

We offer flexible trade terms such as FOB and CIF, and have a professional foreign trade team to assist with customs declaration, sea transportation, documentation and other matters. We provide 7× 24-hour multilingual communication to break down communication barriers in cross-border cooperation.