0102030405

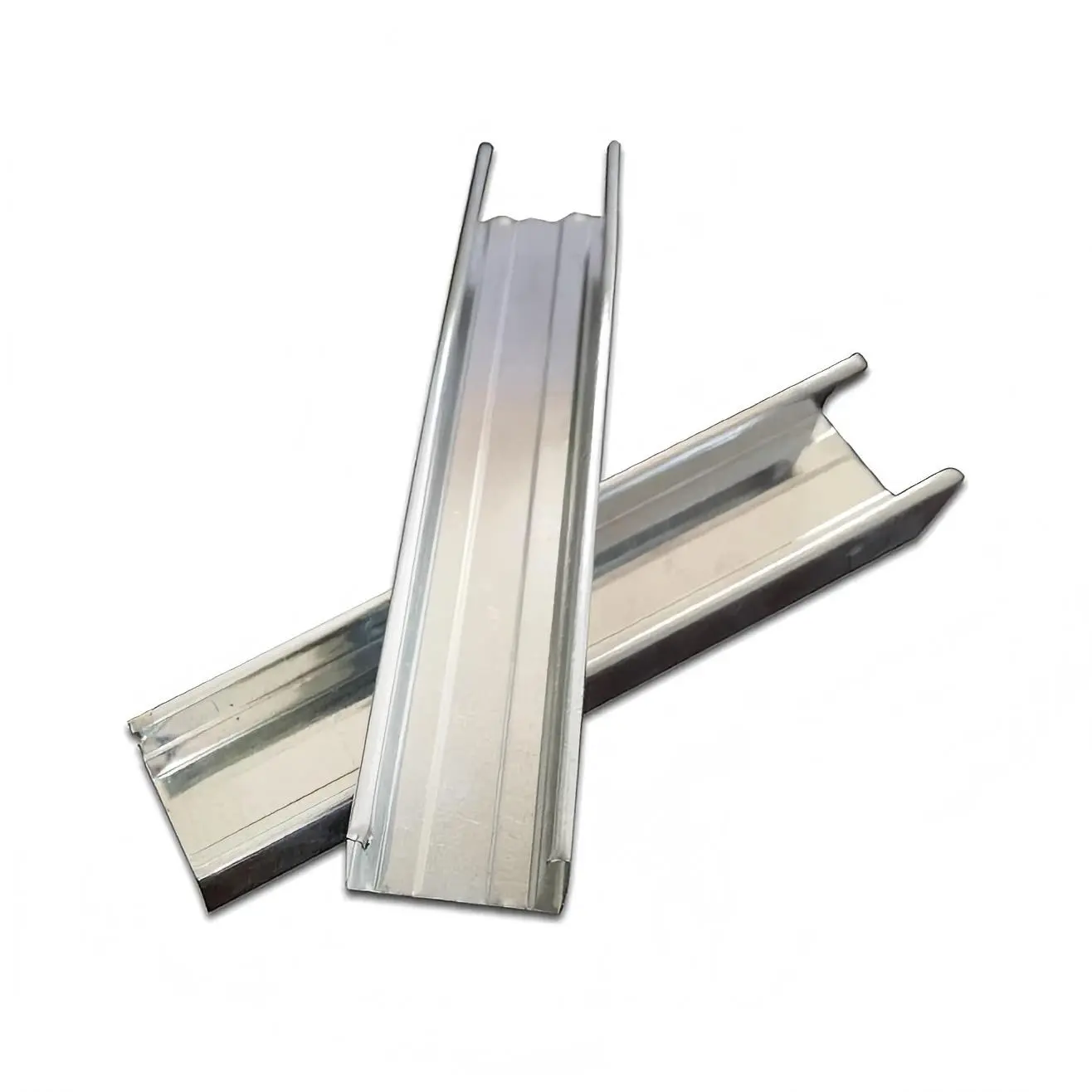

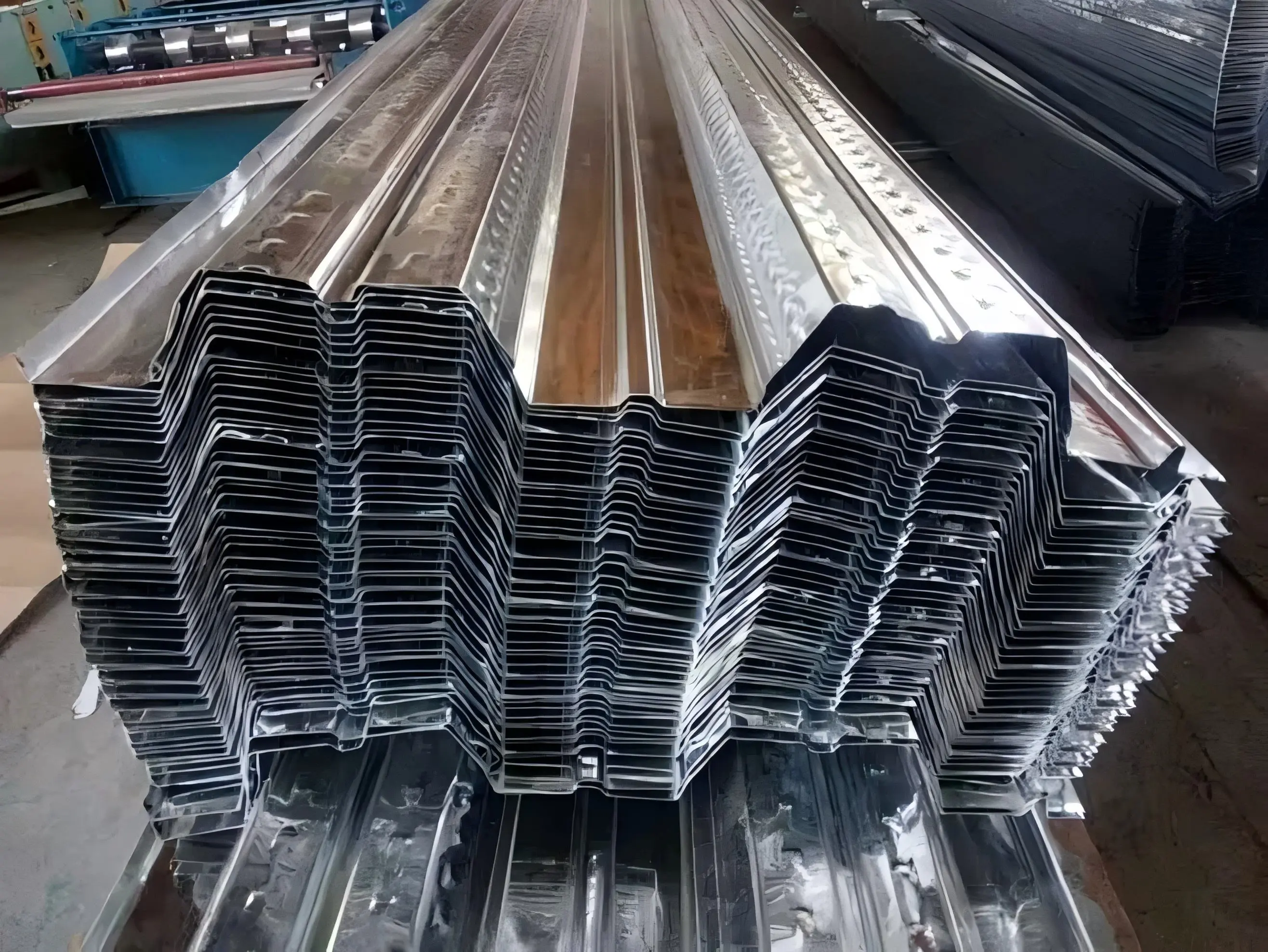

Customized light steel keel: Hot-dip galvanized anti-rust, suitable for various ceiling and partition walls

Production Description

Our company's light steel keel adheres to the concept that "craftsmanship determines quality", strictly controlling the entire process from raw materials to finished products, and creating a core building material that can be trusted in both home and commercial decoration. The raw materials are selected from high-grade Q235 high-quality carbon steel, which undergoes strict composition testing to remove impurities, ensuring that the strength and toughness of the base material meet the standards. The core adopts hot-dip galvanizing process, with a zinc layer thickness of over 85μm. It undergoes three treatments: acid washing, passivation and high-temperature galvanizing. The zinc layer is uniform and dense, with strong adhesion, effectively resisting moisture and corrosion, and has a service life of over 20 years.

The processing stage relies on CNC precision rolling technology. The mold accuracy is controlled within ±0.1mm to ensure uniform wall thickness and standard dimensions of the keel. Seamless interlocking design is adopted at the joints to enhance the overall load-bearing stability. Each batch of products has passed multiple tests such as salt spray corrosion and compressive load-bearing capacity, and complies with the EU CE and domestic GB/T 11981 standards. This eliminates problems such as deformation and rusting from the source of the process, laying a solid safety foundation for ceiling and partition wall projects, and is suitable for various home and commercial decoration scenarios.

Differentiation advantage

| Competitive Dimension | Our Company's Light Steel Keel | Competitors' Trading Company Products |

| Source & Production Control | Direct supply from own factory, full independent control from raw material procurement to finished product delivery, no middleman markup; supports small-batch rush orders and large-volume project orders, delivery cycle shortened by 30% | Mostly sourced from middlemen, relying on third-party factory OEM, no right to speak in production process; unstable supply, long delivery cycle, unable to undertake customized rush orders |

| Core Production Process | Adopts hot-dip galvanizing process with zinc layer thickness over 85μm, through three-step treatment of pickling-passivation-high temperature galvanizing for stronger rust and corrosion resistance; CNC precision rolling with dimensional accuracy of ±0.1mm | Mostly uses electro-galvanizing or thin-zinc-layer hot-dip galvanizing process, zinc layer thickness only 40-60μm, prone to rust; traditional rolling process with large dimensional deviation (over ±0.3mm) |

| Product Quality & Certification | Made of high-grade Q235 carbon steel, flexural strength 25% higher than national standard; certified by EU CE and national GB/T 11981 dual certifications; each batch undergoes salt spray, compression and other multiple tests with 100% qualification rate | Mostly uses ordinary carbon steel, strength only meets the lower limit of national standard, some lack international certifications; only basic appearance inspection is conducted, core indicators such as salt spray corrosion and earthquake resistance are not verified |

| Customization Service Capability | Supports customization of multiple specifications including 75-type, 100-type, 150-type, can adjust wall thickness and length according to project needs; provides one-stop solution for supporting connectors of keels | Only provides conventional fixed specifications, no customization capability; customers need to match connectors by themselves, resulting in cumbersome procurement process |

| After-sales Support System | Provides 10-year rust-proof quality guarantee + lifelong technical guidance; professional installation consultants are assigned for project orders to assist on-site; 24-hour response to quality issues, free replacement and reissue | Quality guarantee is mostly 1-2 years, only covering basic quality problems; no professional technical support, slow after-sales response, complicated return and exchange process |

Application scenarios

Our company's light steel keel, with its advantages of high strength, rust and shock resistance, and easy installation, is widely adapted to diverse needs such as home decoration, commercial decoration, and special scenarios. In home decoration scenarios, it can be used for ceiling keels in living rooms and bedrooms, as well as partition wall frames in kitchens and bathrooms. It is lightweight, environmentally friendly, moisture-proof and rust-proof, meeting the safety and aesthetic requirements of modern home decoration. When renovating old houses, its convenient installation feature can reduce construction interference and efficiently complete the space renewal.

The commercial decoration field covers large-scale decoration of office buildings, shopping malls, hotels, exhibition centers, etc. As the core support for ceilings and partition walls, it has strong load-bearing capacity, high stability, can adapt to complex shape designs, and has a short construction period, significantly improving project efficiency

In addition, it can precisely adapt to scenarios with high structural strength requirements such as factory workshops, warehouses, and underground garages, as well as the construction of prefabricated buildings and temporary buildings, and has become a core basic building material for multi-scenario decoration

The benefits of choosing us

By choosing us as your supplier, you can enjoy multiple core advantages

1.International standard quality guarantee

Our order default rate is 0. We always put the interests of our customers first. Our products have passed international certifications such as CE and ISO. The fire resistance grade and sound insulation performance meet the standards of mainstream markets in Europe, America, Southeast Asia, etc. Each batch of goods is accompanied by an authoritative test report to ensure smooth customs clearance and compliant use in the local area.

2. Stable and efficient supply chain

With our own factory and long-term cooperative logistics providers, we can handle bulk orders of over 100,000 square meters. The transportation method and delivery time can be communicated at any time. We have sufficient inventory of goods, effectively avoiding the risk of supply disruption and ensuring the progress of our customers' projects.

3. Customized service capabilities

The size, thickness and surface treatment (such as moisture-proof coating, antibacterial process) can be adjusted according to customer requirements, or a customized solution can be formulated for you. Neutral packaging or customization of customer brands is supported to meet the differentiated needs of different markets.

4. Full-process support for foreign trade

We offer flexible trade terms such as FOB and CIF, and have a professional foreign trade team to assist with customs declaration, sea transportation, documentation and other matters. We provide 7× 24-hour multilingual communication to break down communication barriers in cross-border cooperation.