High-Quality Waterproof And Fire-Resistant Calcium Silicate Board

Products Features

1. Non-combustible (Class A1 Fire Rating):

Calcium silicate board is a non-combustible material with a Class A1 fire rating. In the event of a fire, it will neither burn nor release toxic smoke.

2. Excellent Water Resistance:

It performs exceptionally well in high-humidity areas such as bathrooms and restrooms, maintaining stable performance without swelling or deformation.

3.High Strength:

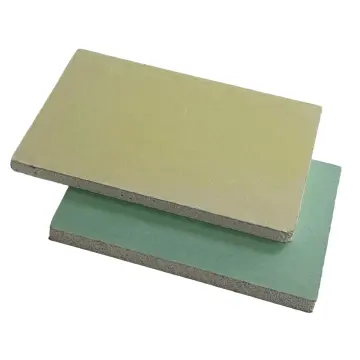

A 6mm thick calcium silicate board is significantly stronger than a 9.5mm standard gypsum board. Walls made from calcium silicate boards are solid, reliable, and resistant to damage or cracking.

4.Dimensional Stability:

Produced under strict quality control with an advanced formula, calcium silicate boards maintain ideal expansion and shrinkage rates under changing moisture conditions.

5.Thermal and Sound Insulation:

With excellent thermal insulation properties, a 10mm calcium silicate partition outperforms ordinary brick walls in heat retention. It also provides effective sound insulation.

6.Durability and Resistance to Corrosion:

The board is stable in performance, resistant to acid, alkali, moisture, mold, and insect damage, ensuring a long and reliable service life.

Production Process

There are several production methods for calcium silicate boards, including molding, slurry flow-on, and papermaking processes.

The most commonly used method is the extrusion process. In this method, raw materials are fully mixed and matured according to the designed formulation, then shaped through a roller press extrusion, followed by high-temperature curing and setting.

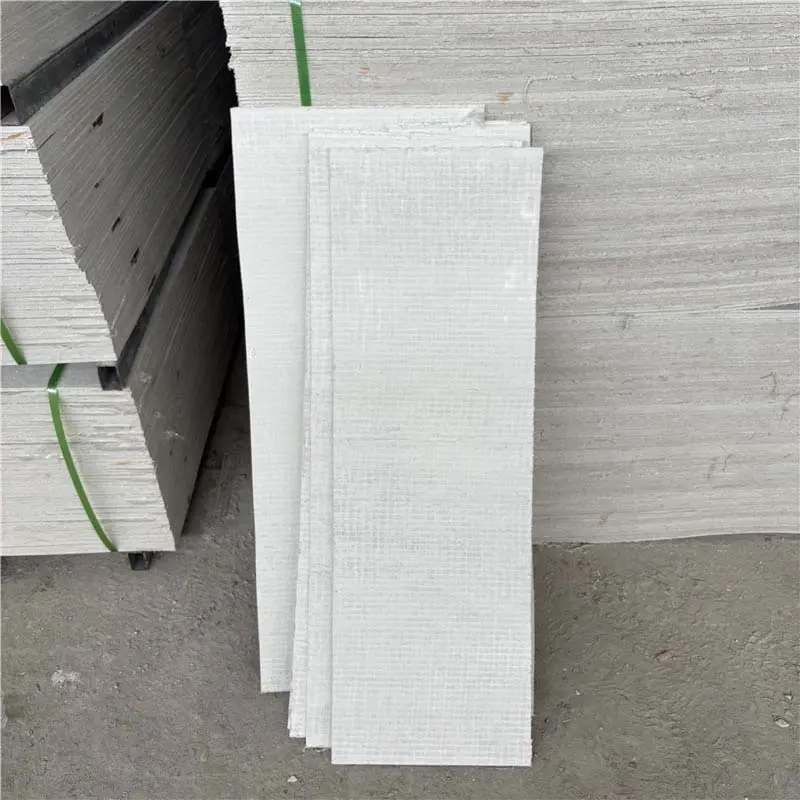

The standard board dimensions are 2440 mm in length and 1220 mm in width, with commonly used thicknesses ranging from 4 mm to 30 mm.

Usage Scenarios

Application Areas

Commercial Buildings: Office towers, entertainment venues, shopping malls, hotels

Industrial Buildings: Factories, warehouses

Residential Buildings: Modern housing, renovation projects

Public Facilities: Hospitals, theaters, railway stations

Main Uses

Calcium silicate boards are widely used in:

Walls, ceilings, and flooring systems

Furniture backing panels

Roadside sound barriers and acoustic panels

Ship bulkheads and air ducts

Industrial boards for noise reduction and insulation

Sound-absorbing walls and ceilings

Cast-in-place walls and composite wall panel surfaces

Material Styles

Calcium silicate board is a type of board made from loose short fibers such as inorganic mineral fibers or cellulose fibers as reinforcement materials, with siliceous and calcareous compounds as the main cementing agents.

The production process involves pulping, forming, and accelerated curing under high-temperature, high-pressure saturated steam, during which a calcium silicate hydrate gel is formed, giving the board its structural integrity.

This board is a high-performance, new-generation building and industrial material, offering excellent properties such as fire resistance, moisture resistance, sound insulation, insect resistance, and long-term durability. It is an ideal choice for ceiling systems and partition walls in both residential and commercial applications.