High-Performance Calcium Silicate Boards for Interiors

Products Features

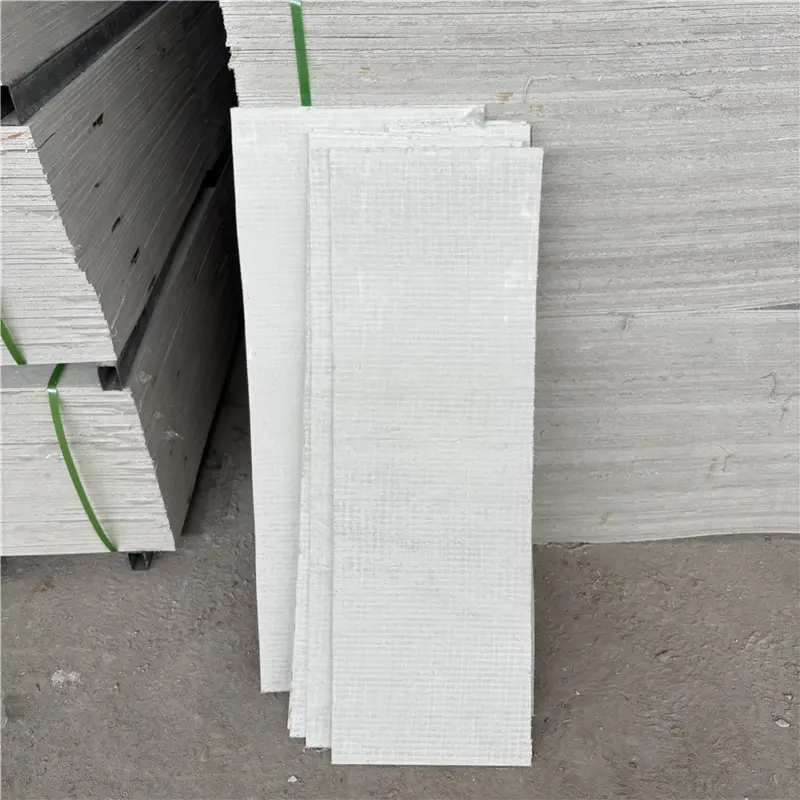

Production Process

The production process begins with mixing siliceous (quartz sand) and calcareous (lime) materials with cellulose fibers and water. The slurry is shaped into boards through a forming process, then cured in high-temperature autoclaves to achieve full hydration and structural integrity. After curing, boards are dried, trimmed, and optionally surface-treated. The entire process follows ISO and CE standards for safety, performance, and environmental impact. Final products are subject to rigorous quality control, ensuring uniform thickness, mechanical strength, and low shrinkage.

Usage Scenarios

Calcium silicate boards are widely used in interior wall and ceiling systems, especially where fire protection and moisture resistance are key. Common applications include partition walls in office buildings, hospitals, schools, shopping malls, industrial plants, and residential projects. They are also suitable as backing boards for tiles in bathrooms and kitchens. Their fireproof and sound-insulating properties make them ideal for high-traffic and high-risk areas. Lightweight and easy to install with screws or adhesives, they are a popular solution for both new construction and interior renovations.

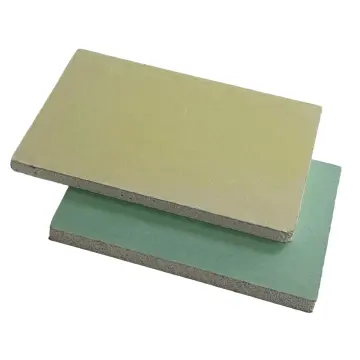

Material Styles

We offer calcium silicate boards in a range of sizes and thicknesses to meet different project needs. Standard dimensions include 1220×2440 mm with thicknesses ranging from 4 mm to 20 mm. Surface options include smooth, textured, and pre-coated finishes. Boards can be painted, wallpapered, or tiled according to design preferences. Custom sizes and fire-rated versions are available upon request. All boards are compatible with metal or wooden framing systems, allowing for flexible and efficient installation on site.