0102030405

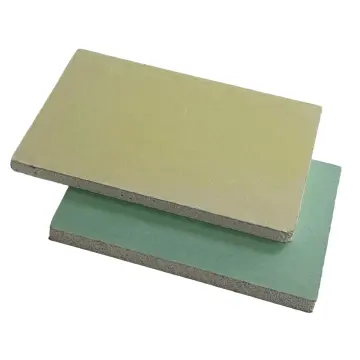

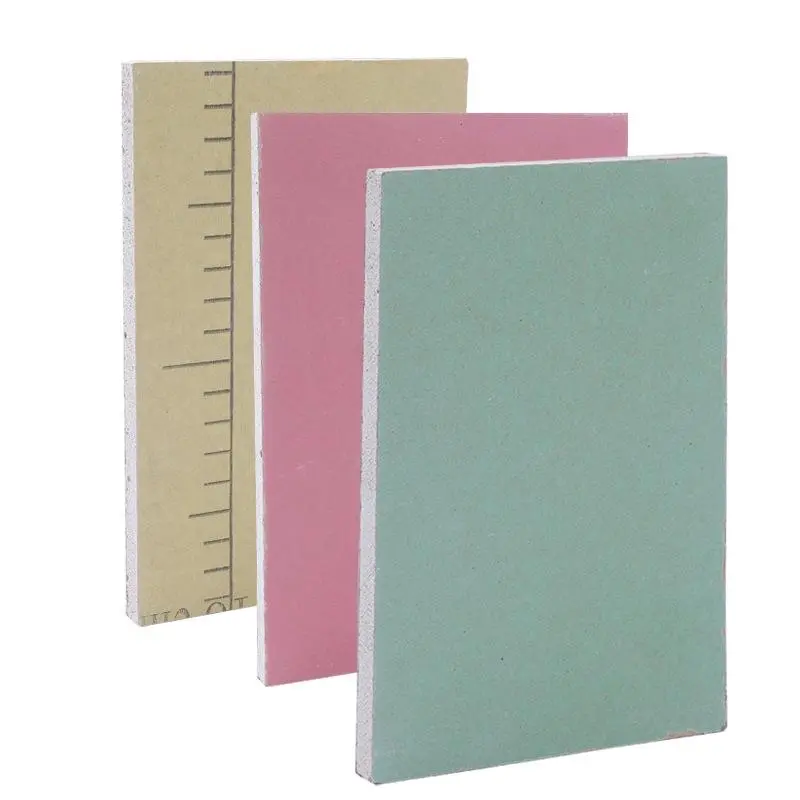

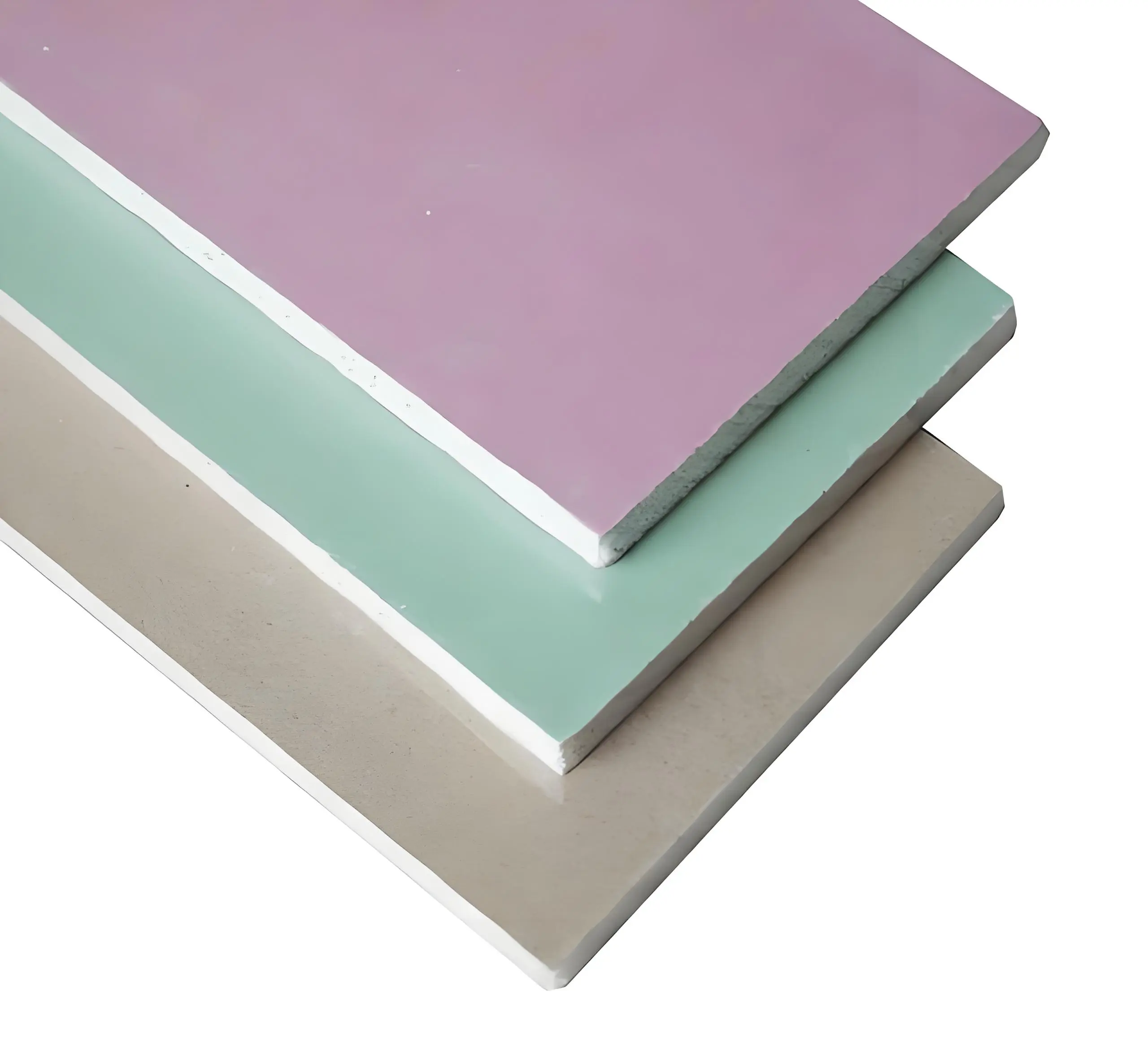

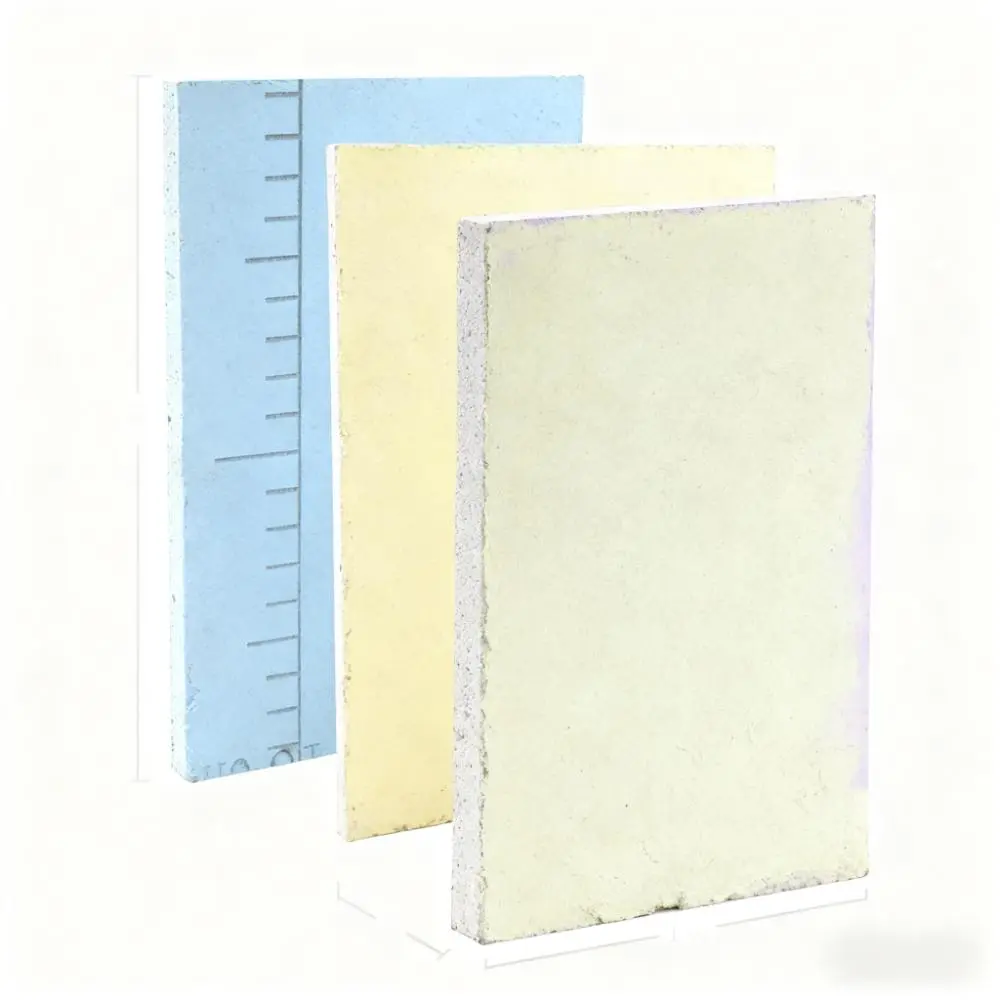

Colorful decorative gypsum boards are available in multiple colors for interior shaping

Production Description

Our company's gypsum boards are easy to install and quality is guaranteed: Before construction, remove the damaged and damp gypsum boards and decorative panels, and at the same time check the keel framework (ensuring that the hangers are straight, the keel spacing is ≤500mm, and the main accessories are firmly connected, etc.). When cutting gypsum board, use a blade to cut the front side and then break it, and then cut the back side to ensure that the edge is straight and square. When laying, the long side of the gypsum board should be perpendicular to the supporting keel, and the joints should be close but not forcefully pressed into position. Nails should be laid piece by piece from the corners or the middle area of the board. It is fixed with self-tapping screws. The distance between the nails at the edge of the board is 150-200mm, and the distance between the nails at the center of the board is 200-300mm. The nail heads are embedded in the board surface by 0.5-1mm, and the nail holes are filled flat with gypsum putty. For the treatment of the board joints, after filling the edge joints with putty, apply perforated paper tape. After cleaning the cut edge joints, fill them with gypsum putty. In addition, the gypsum boards on both sides of the keel should be staggered in arrangement. If it is a double-layer board, the joints of the two layers should also be staggered to ensure the stability of the structure and the smoothness and beauty of the finish after installation

Differentiation advantage

| Production Process Link | Our Company's Process | Peers' Conventional Process | Competitive Advantages |

| Raw Material Selection | High-purity gypsum (≥95%) + food-grade additives, with 3 rounds of magnetic separation + 2 rounds of screening for impurity removal | Ordinary gypsum (80%-85%) + industrial-grade additives, only 1 round of basic screening | Base material density increased by 15% for better crack resistance; harmful substances far below national standards, with superior environmental performance |

| Core Molding | Full-automatic CNC casting (tolerance ≤ 0.1mm) + 7-layer gradient pressing, with real-time dimension monitoring | Semi-automatic casting (tolerance ≥ 0.3mm) + 3-4 layers of pressing, only end-of-line manual sampling inspection | Board flatness ≤ 0.2mm/2m (peers: ≤ 0.5mm/2m); flexural strength increased by 30% |

| Low-Temperature Drying | Closed-loop heat pump temperature control (45-50℃), 24-hour drying, real-time humidity control | Open hot-air drying (temperature fluctuation ±8℃), 36-48-hour drying, relying on natural humidity | Moisture content stably at 8%-10% (peers: 12%-15%); no warping during later installation |

| Functional Enhancement | Double-sided penetrating water repellent + Class A fire-resistant coating, 100% coverage | Surface-sprayed water repellent + Class B1 fire-resistant filler, 85%-90% coverage | Water resistance durability doubled; 100% compliance with fire resistance standards, suitable for humid/high-temperature scenarios |

| Full-Process Precision Control | Online laser inspection (30 points per meter) + 100% manual re-inspection | End-of-line sampling inspection (30%-50%), 10-15 points per meter | Ex-factory qualification rate 99.8% (peers: 95%-97%); reduced cutting waste during installation |

Application scenarios

Our company's gypsum boards are suitable for various scenarios such as home decoration and commercial decoration, and they are both practical and adaptable. In home decoration, the E0 grade eco-friendly formula is the first choice for the ceilings and partition walls in the living room and bedroom. It is free of formaldehyde and odor, ensuring a healthy living environment. The smooth surface of the board is also convenient for subsequent painting and wallpaper application. For the kitchen and bathroom, waterproof models are used. After 24 hours of soaking, the water absorption rate is ≤10%, and they can withstand moisture without getting moldy. In the industrial decoration scene, the large partition walls and shaped ceilings in office buildings and shopping malls, relying on their high flexural strength (30% higher than that of their peers), are less likely to be damaged by the vibration of people flow. For schools, hospitals and other places, choose the A-level fireproof model, which complies with fire protection regulations. Moreover, the board surface is easy to clean, suitable for high-frequency usage needs, and fully covers various decoration requirements.

The benefits of choosing us

By choosing us as your supplier, you can enjoy multiple core advantages

1.International standard quality guarantee

Our order default rate is 0. We always put the interests of our customers first. Our products have passed international certifications such as CE and ISO. The fire resistance grade and sound insulation performance meet the standards of mainstream markets in Europe, America, Southeast Asia, etc. Each batch of goods is accompanied by an authoritative test report to ensure smooth customs clearance and compliant use in the local area.

2. Stable and efficient supply chain

With our own factory and long-term cooperative logistics providers, we can handle bulk orders of over 100,000 square meters. The transportation method and delivery time can be communicated at any time. We have sufficient inventory of goods, effectively avoiding the risk of supply disruption and ensuring the progress of our customers' projects.

3. Customized service capabilities

The size, thickness and surface treatment (such as moisture-proof coating, antibacterial process) can be adjusted according to customer requirements, or a customized solution can be formulated for you. Neutral packaging or customization of customer brands is supported to meet the differentiated needs of different markets.

4. Full-process support for foreign trade

We offer flexible trade terms such as FOB and CIF, and have a professional foreign trade team to assist with customs declaration, sea transportation, documentation and other matters. We provide 7× 24-hour multilingual communication to break down communication barriers in cross-border cooperation.