Galvanized Light Steel Keel For Drywall

Application scenarios

Ceiling construction: Suitable for full space ceilings such as living rooms, bedrooms, kitchens, bathrooms, etc. Create a simple design with gypsum board to prevent the wooden keel from deforming due to moisture. In damp areas such as kitchens and bathrooms, its moisture-proof and rust-proof properties can prevent the ceiling from cracking and mold growth, thereby extending its service life.

Wall shaping and base: It is used for the framework construction of TV background walls and headboard background walls, which can firmly fix wood veneer panels, soft packages and other decorative materials, and easily achieve three-dimensional shaping. It can also be used as a base layer for walls to enhance their flatness and lay a foundation for subsequent tiling and painting.

Space partitioning: Suitable for scenarios such as creating a small study in the living room or a storage area on the balcony. Combined with sound insulation cotton and gypsum board, it neither takes up too much space nor blocks out some noise. Moreover, it is easy to disassemble and does not require major alterations when adjusting the layout later, flexibly adapting to changes in living needs.

Production Description

The construction process of light steel keel partition walls

Preparatory work and positioning: Prepare all necessary materials such as light steel keels (top and bottom, vertical and horizontal), gypsum boards, screws, sound insulation cotton, etc. Mark lines on the floor, ceiling and walls, indicating the position of partition walls, the spacing of keels and the size of door openings to ensure the accuracy of the reference.

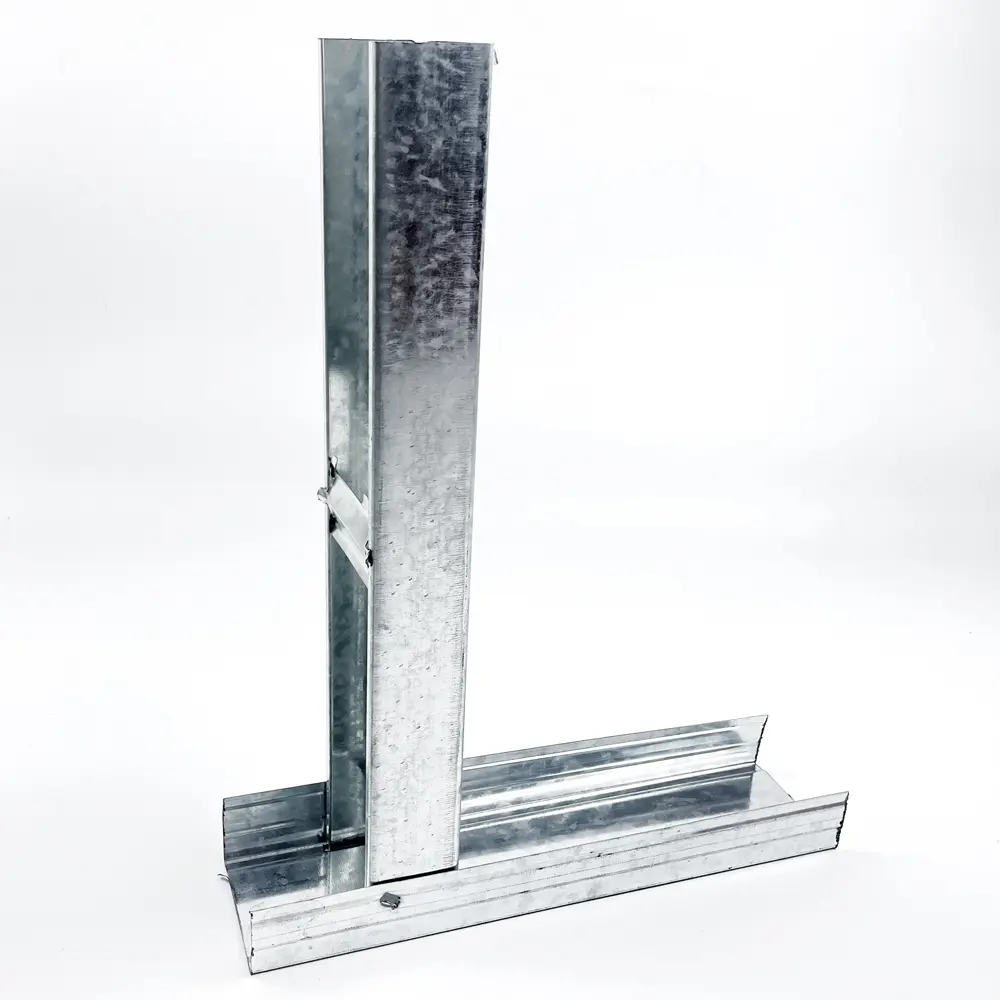

Installation of the top and bottom keel: Fix the top and bottom keel (U-shaped) along the marked lines to the ground or top surface, and secure it with expansion screws or nail guns. The spacing should be no more than 600mm. Check the verticality and levelness.

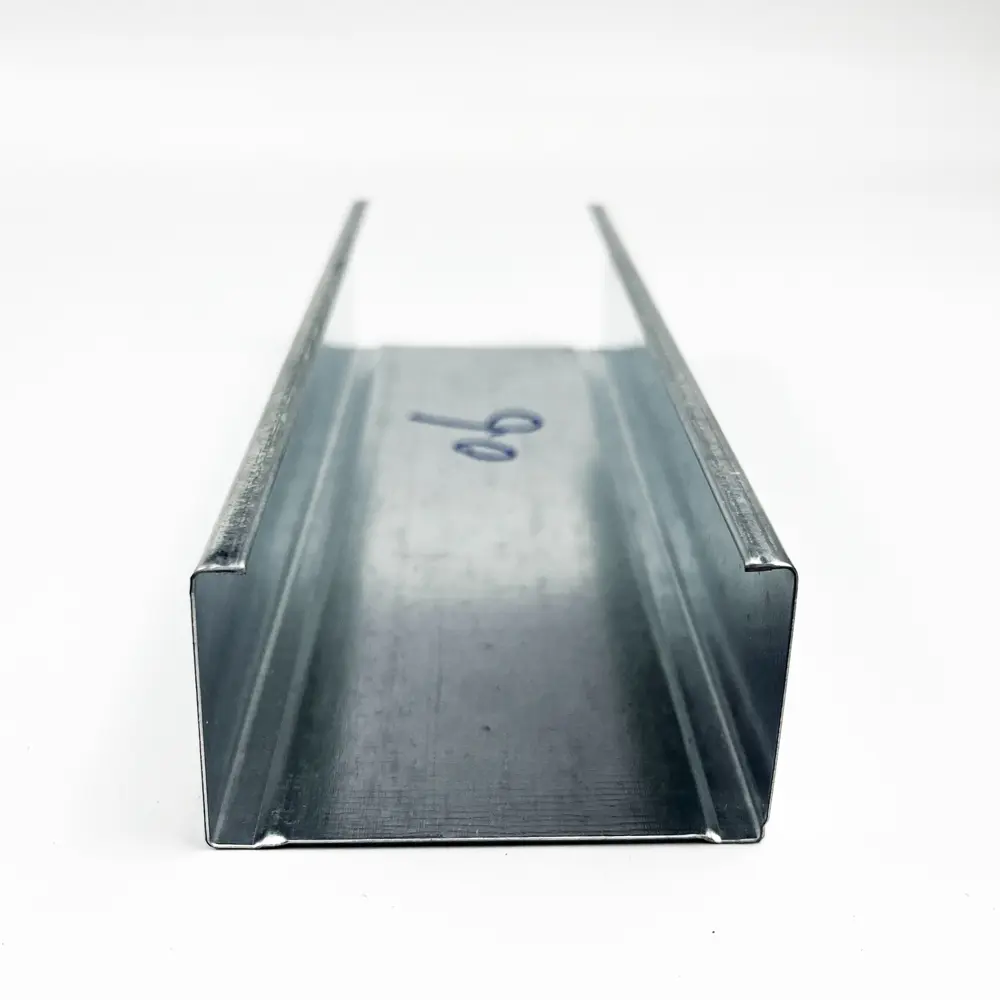

Install vertical and horizontal keels: Insert the vertical keel (C-shaped) into the top and bottom keels, with the spacing determined according to the panel specifications (mostly 600mm). Reinforcing keels need to be added at the door opening. Install the horizontal keel (connect the vertical keel) again. When the height exceeds 3 meters, add the supporting keel.

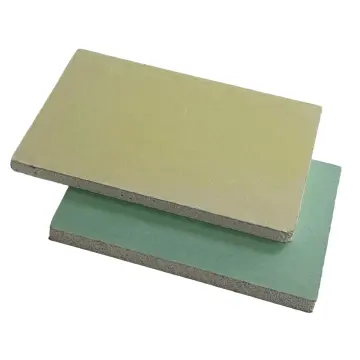

Pre-buried pipelines and sealing plates: Pre-buried water and electricity pipelines in the cavity of the keel. Then, fix the gypsum board on both sides of the keel with self-tapping screws, with a screw spacing of 150-200mm and staggered board joints. Finally, handle the board joints (apply bandages and apply putty) to complete the construction.

Differentiation advantage

The raw materials and processes are more stringent: high-quality Q235 cold-rolled steel plates are carefully selected, and the thickness error of the raw materials is strictly controlled within ±0.03mm, far exceeding the industry's conventional standard of ±0.05mm. The fully automatic precision cold-bending forming process is adopted, with the flatness error of the keel section ≤0.5mm. It is combined with double-layer hot-dip galvanizing treatment (zinc layer thickness up to 90g/㎡), and the moisture-proof and rust-proof ability is 60% higher than that of ordinary galvanized products, avoiding deformation and rusting problems from the source.

More reliable performance and quality: Each batch of products has passed the bending resistance and static load load-bearing tests. They can maintain structural stability without the risk of deformation or cracking in extreme environments ranging from -30 ℃ to 70℃, and the product qualification rate is always 100%. The load-bearing capacity of the keel of the same specification is 18% higher than that of its peers, and it can be adapted to heavy decorative surfaces such as stone and thick wood veneer panels.

More flexible service and adaptation: Supports customization of multiple cross-sections such as U-shaped and C-shaped, responds to demands within 24 hours, and the delivery cycle is 25% shorter than that of peers. It is equipped with highly adaptable galvanized connectors and offers free installation technical manuals and online guidance

The benefits of choosing us

By choosing us as your supplier, you can enjoy multiple core advantages

1.International standard quality guarantee

Our order default rate is 0. We always put the interests of our customers first. Our products have passed international certifications such as CE and ISO. The fire resistance grade and sound insulation performance meet the standards of mainstream markets in Europe, America, Southeast Asia, etc. Each batch of goods is accompanied by an authoritative test report to ensure smooth customs clearance and compliant use in the local area.

2. Stable and efficient supply chain

With our own factory and long-term cooperative logistics providers, we can handle bulk orders of over 100,000 square meters. The transportation method and delivery time can be communicated at any time. We have sufficient inventory of goods, effectively avoiding the risk of supply disruption and ensuring the progress of our customers' projects.

3. Customized service capabilities

The size, thickness and surface treatment (such as moisture-proof coating, antibacterial process) can be adjusted according to customer requirements, or a customized solution can be formulated for you. Neutral packaging or customization of customer brands is supported to meet the differentiated needs of different markets.

4. Full-process support for foreign trade

We offer flexible trade terms such as FOB and CIF, and have a professional foreign trade team to assist with customs declaration, sea transportation, documentation and other matters. We provide 7× 24-hour multilingual communication to break down communication barriers in cross-border cooperation.