0102030405

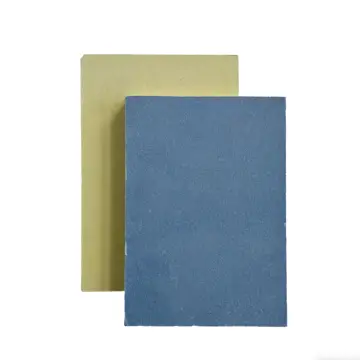

Fire-resistant gypsum board for ceilings

Production Description

Our company's production process of refractory gypsum board focuses on the core demand of "high fire resistance", and controls the quality from the source. The raw materials are carefully selected from high-purity natural gypsum, combined with exclusively developed refractory additives (including glass fiber and inorganic refractory fillers), and precisely proportioned and mixed to enhance the high-temperature resistance of the board.

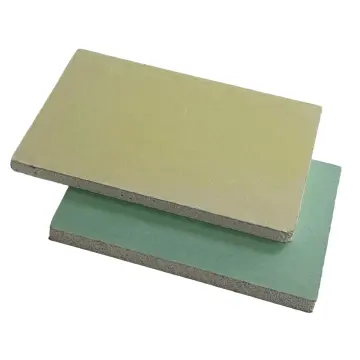

The stirring stage adopts a high-speed homogenization process to ensure the uniform dispersion of refractory components and avoid local performance differences. During the forming stage, the gypsum slurry is closely combined with the reinforced glass fiber mesh through multi-layer bonding technology, enhancing the structural stability and crack resistance of the board.

The key drying process adopts segmented temperature control technology, first low-temperature setting and then high-temperature curing. This not only ensures the full development of gypsum crystals but also prevents the failure of additives. Eventually, the fire resistance limit of the board reaches over 4 hours, far exceeding the standard of 1.5 hours for ordinary gypsum boards. Moreover, no toxic gases are released at high temperatures, and the entire process complies with environmental protection production requirements.

Differentiation advantage

Our company's refractory gypsum board has a significant competitive edge. The raw material end carefully selects high-purity natural gypsum and combines it with exclusively developed refractory additives to lay a solid foundation for high refractoriness from the source. In contrast, most competing products use ordinary gypsum and conventional fillers.

In terms of craftsmanship, high-speed homogeneous stirring ensures the even distribution of refractory components, multi-layer pressing technology enhances structural stability, and segmented temperature-controlled drying guarantees performance. These exclusive processes enable the product to have a fire resistance limit of over 4 hours, far exceeding the 1.5-hour standard for ordinary gypsum boards, and also offer superior crack resistance.

Meanwhile, the product does not release any toxic gases at high temperatures, and the entire process is environmentally friendly, taking into account both safety and green demands. In addition, the performance advantages lead to a longer service life, reduce the later replacement costs for customers, and the overall cost performance far exceeds that of similar products, making it highly competitive in the engineering and home decoration markets.

Application scenarios

Fire-resistant gypsum board is widely used in areas where fire safety is paramount, such as stairwells, elevator shafts, and mechanical rooms in commercial buildings. It is also suitable for residential applications, including garages, basements, and shared walls in multi-family dwellings. In industrial settings, the board is used to create fire barriers and protective enclosures for electrical and mechanical systems. Its versatility and reliability make it a preferred choice for architects and builders aiming to meet stringent fire safety regulations.

The benefits of choosing us

By choosing us as your supplier, you can enjoy multiple core advantages

1.International standard quality guarantee

Our order default rate is 0. We always put the interests of our customers first. Our products have passed international certifications such as CE and ISO. The fire resistance grade and sound insulation performance meet the standards of mainstream markets in Europe, America, Southeast Asia, etc. Each batch of goods is accompanied by an authoritative test report to ensure smooth customs clearance and compliant use in the local area.

2. Stable and efficient supply chain

With our own factory and long-term cooperative logistics providers, we can handle bulk orders of over 100,000 square meters. The transportation method and delivery time can be communicated at any time. We have sufficient inventory of goods, effectively avoiding the risk of supply disruption and ensuring the progress of our customers' projects.

3. Customized service capabilities

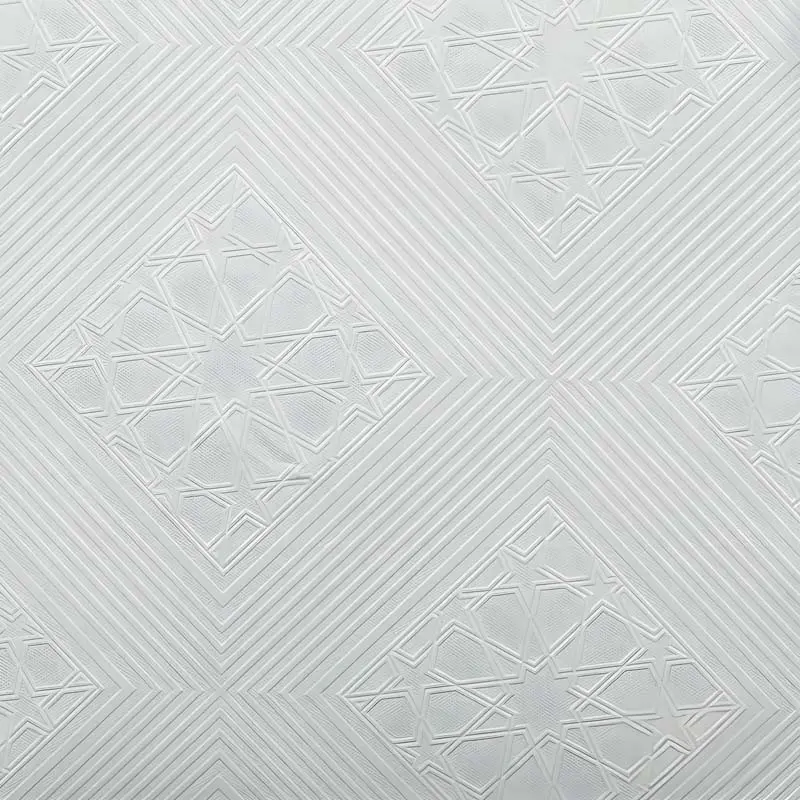

The size, thickness and surface treatment (such as moisture-proof coating, antibacterial process) can be adjusted according to customer requirements, or a customized solution can be formulated for you. Neutral packaging or customization of customer brands is supported to meet the differentiated needs of different markets.

4. Full-process support for foreign trade

We offer flexible trade terms such as FOB and CIF, and have a professional foreign trade team to assist with customs declaration, sea transportation, documentation and other matters. We provide 7× 24-hour multilingual communication to break down communication barriers in cross-border cooperation.